MF1200 D

IMSA simple 3-4 axes solution for blocks, mold inserts and plates.

The IMSA deep hole drilling machine MF1200D can also be used to drill centered and off-center deep holes in cylindrical parts.

Drilling depth in single operation max. 1200 mm. Table load 4000 kg.

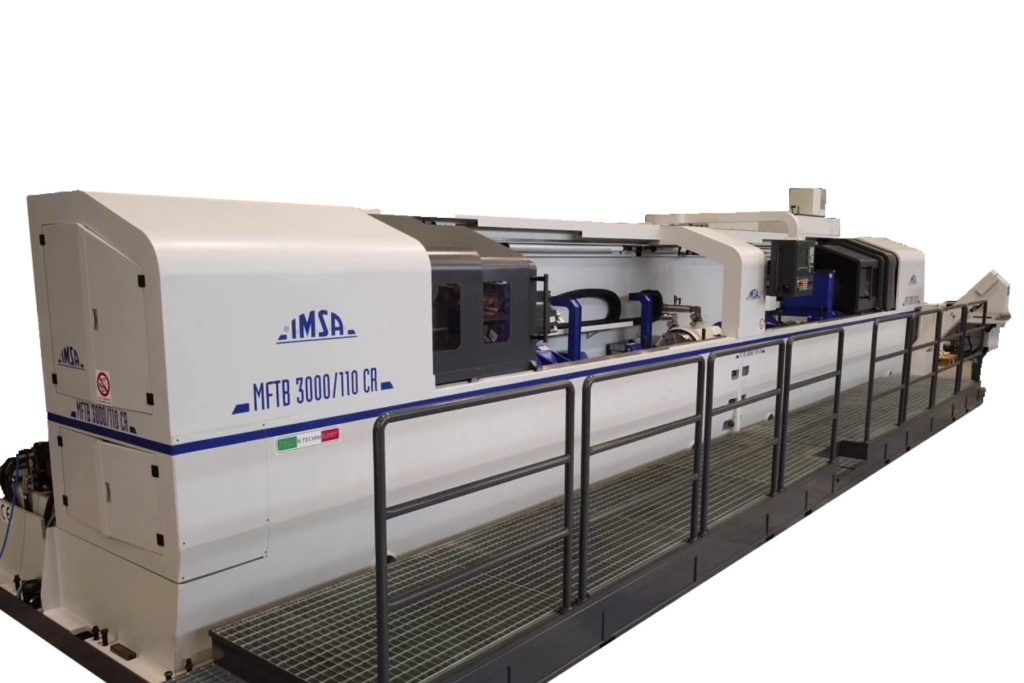

MFTB 1000/76 GDK – MFTB 2000 /76 GDK – MFTB 3000 /76 GDK

Centerline deep hole drilling machine for cylindrical parts. In the intermediate diameter range between the Gun Drilling and the BTA Drilling, we propose a Double-Setup flexible solution we called IMSA “GDK” System. This enables you to better take advantage of both tool types. Drilling diameter range with gun drill tools: 8 -25 mm solid; drilling diameter range with BTA tools: 20 – 76 mm solid.

SPECIAL OFFER | MF1500B2 | IMSA DEEP HOLE DRILLING MACHINE

Pre-owned IMSA machine fully revamped and re-registered by the manufacturer. Cnc Gun Drilling Machine for hole Ø 5-25 mm solid, max. drilling depth 1.500 mm (V-axis). Table load 10.000 kg. Auxiliary ISO40 spindle.

MFT 750/2T CR – MFT 1500/2T CR

Centerline deep hole drilling machines. These “2T” machines are equipped with a single carriage with two spindles, enabling you to drill 2 identical parts in each drilling cycle. Method: gun drilling. Workpiece in counter-rotation. Drilling diameters: 6 – 24 mm. Drilling depth (respectively) 750 mm, 1500 mm.

MFT 1000 /2Ti CR – MFT 1500 /2Ti CR

Centerline deep hole drilling machines. These “2Ti” machines are equipped with 2 independent drilling carriages that enable you to drill 2 different workpieces in each cycle. Method: gun drilling. Workpiece in counter-rotation. Drilling diameters: 6 – 25 mm. Drilling depth (respectively) 1000 mm, 1500 mm.

MFT 1000EVO

Centerline deep hole drilling machine. Single spindle. Drilling method: gun drill tool. Workpiece in counter-rotation. Drilling diameters: 4 – 25 mm. Drilling depth (160 x Ø) max. 1000 mm. This EVO version manages pressure and flow by an inverter; moreover, it enables a very quick setup thanks to full-cnc movements.

MFTB 3300 /110EVO

Centerline deep hole drilling machine specific for aeronautical shafts, martensitic stainless steels in particular. Single spindle. Drilling method: by BTA tools. Workpiece in counter-rotation. Drilling diameters: 30 – 110 mm. Drilling depth: max. 3300 mm.

MFTB1000/51 GDK – MFTB1500/51 GDK – MFTB2000/51 GDK

Centerline deep hole drilling machine for cylindrical parts. In the intermediate diameter range between the Gun Drilling and the BTA Drilling, we propose a Double-Setup flexible solution we called IMSA “GDK” System. This enables you to better take advantage of both tool types. Drilling diameter range with gun drill tools: 8 -24 mm; drilling diameter range with BTA tools: 18 – 51 mm.

MFTB1000/51 CR – MFTB1500/51 CR – MFTB2000/51 CR

Centerline deep hole drilling machine for cylindrical parts. Method: BTA drills. Workpiece in counter-rotation. Drilling depth (respectively) 1000 mm, 1500 mm, 2000 mm. Drilling diameter: 18-51 mm.

MFTB1000/76 CR – MFTB2000/76 CR – MFTB3000/76 CR

Centerline deep hole drilling machine for cylindrical parts. Deep drilling method: BTA/STS. Drilling depth (respectively) 1000 mm, 2000 mm, 3000 mm. Drilling diameter range: 20 – 76 mm.

MFTB1000/110 – MFTB2000/110

Centerline deep hole drilling machine for steel shafts and other cylindrical parts that have to be drilled on their rotation axis. Deep drilling method: BTA/STS. Drilling depth (respectively) 1000 mm, 2000 mm. Drilling diameter range: 20 – 110 mm (in option, up to 135 mm in counter-boring).

MFTB2000 /200

Centerline deep hole drilling machine for steel shafts and other cylindrical parts that have to be drilled on their rotation axis. Deep drilling method: BTA/STS. Drilling depth: 2000 mm. Drilling diameter range: 50 -200 mm.

SPECIAL OFFER | MF650A | IMSA DEEP HOLE DRILLING MACHINE

CNC Gun Drilling Machine for hole Ø 4-20mm solid, max. drilling depth 650 mm (Z axis).

SPECIAL OFFER | MF1000B2 | IMSA DEEP HOLE DRILLING MACHINE

Pre-owned IMSA machine fully revamped and re-registered by the manufacturer. Cnc Gun Drilling Machine for hole Ø 4-20 mm solid, max. drilling depth 1000 mm (V-axis). Table load 4000 kg. Auxiliary ISO40 spindle

MFT 1000 /32 CR – MFT 1500 /32 CR

Centerline deep hole drilling machines for steel shaft and other cylindrical parts that have to be drilled on their rotation axis until Ø32, such as: gear shafts, aerospace industry, flanges for industrial applications. Single spindle. Method: gun drilling. Drilling diameters: 6 – 32 mm. Drilling depth (respectively) 1000 mm, 1500 mm.

MFT 1000 /43CR – MFT 1500 /43CR

Centerline deep hole drilling machines for steel shaft and other cylindrical parts that have to be drilled on their rotation axis until Ø43, such as: gear shafts, aerospace industry, flanges for industrial applications. Single spindle. Method: gun drilling. Drilling diameters: 8 – 43 mm. Drilling depth (respectively) 1000 mm, 1500 mm.

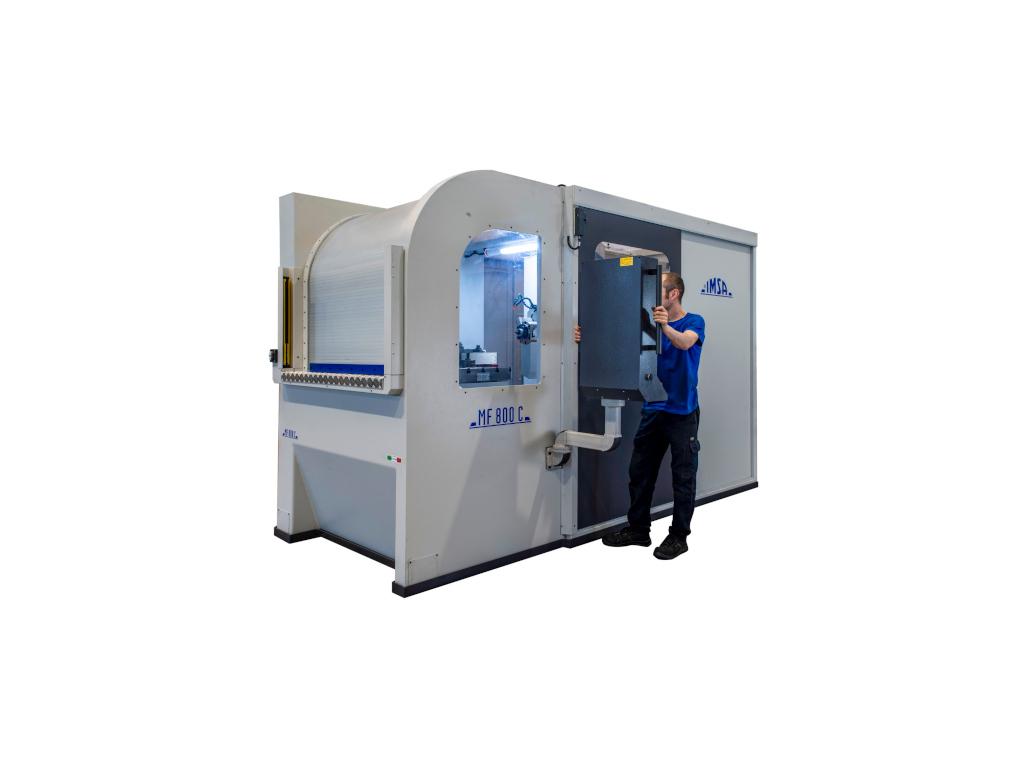

MF800C

IMSA’s simplest deep drilling machine for blocks and plates, and for off-center deep holes in cylindrical parts. Drilling depth max. 800 mm. Table load: 2000 kg on optional rotary table; 4000 kg on standard fixed table.

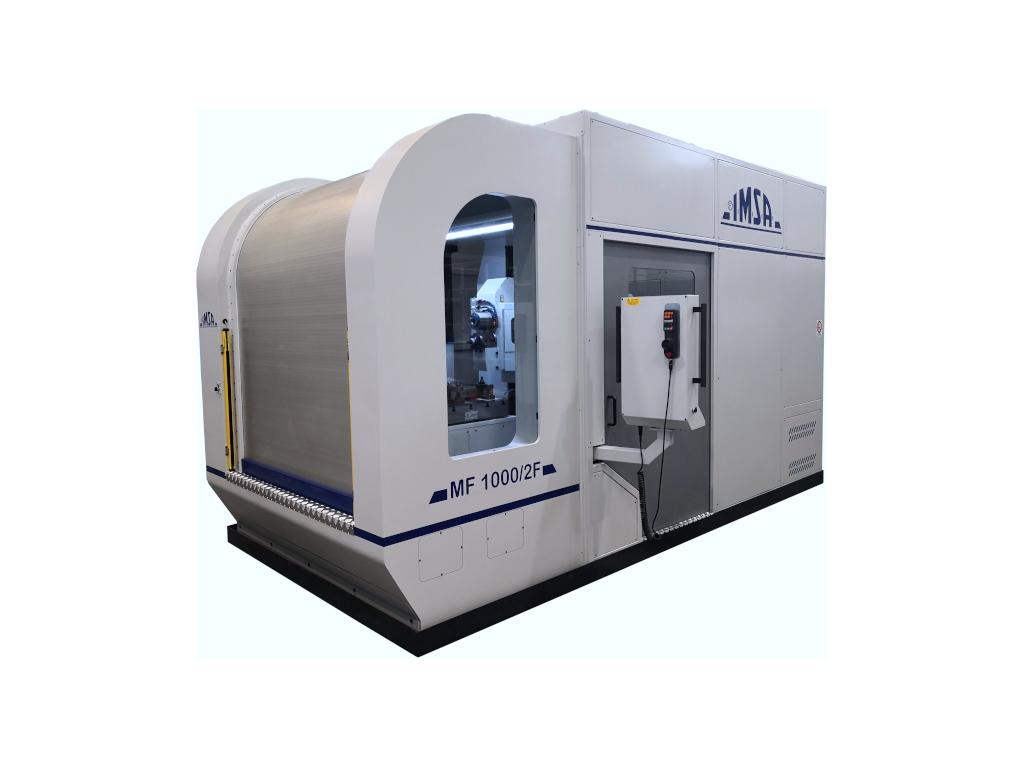

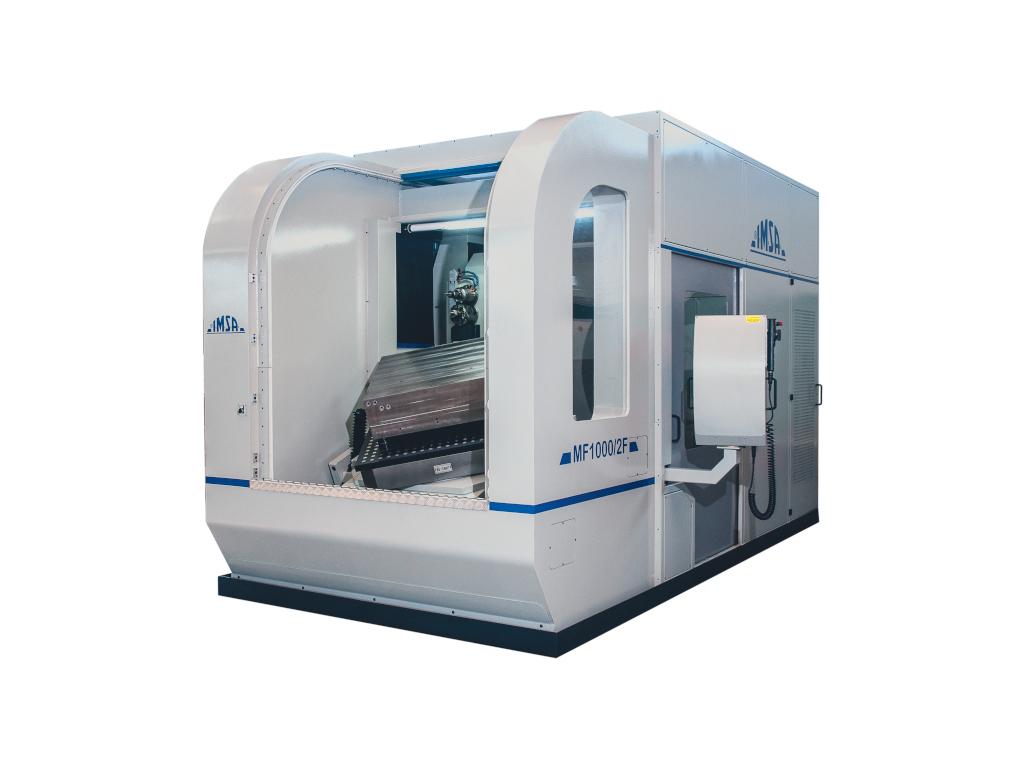

MF1000/2F with Rotary Table

Gun drilling and milling machine for small to middle-size molds. Straight (3-axis) and single-angle (4-axis) drillings: this machine version is equipped with a rotary table.

MF 500/6T

Deep hole drilling machine with 6 independent gundrilling heads for glass bottle moulds

MF700/3000

Single-spindle gundrilling machine with increased horizontal travel.

MF 350/4TA

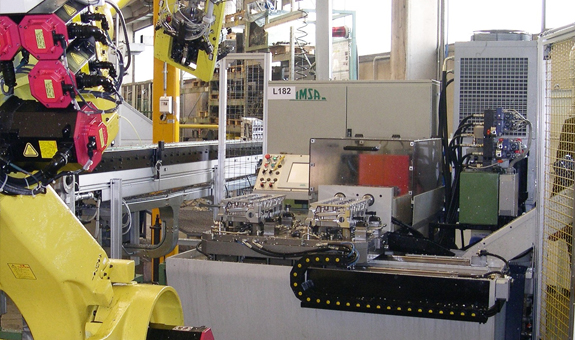

Deep hole drilling special machine with 4 independent heads integrated in automatic production line type FMS.

MF 600/2T

Deep hole drilling machine with two independent heads, integrated in production cell with autoloading. Automotive industry.

MFT6000/CR

Centerline deep hole drilling machine for cylindrical parts. Gundrilling tool, workpiece in counter-rotation, on-center drilling. Drilling depth 6 meters.

MF 500 4+4T

Deep hole drilling solution for automotive industry. Machine with 4+4 opposed heads integrated in production cell.

MF1000 /2C

Gun drilling and milling machine molds and mechanical parts up to 2 or 4 tonnes, depending on the chosen table.

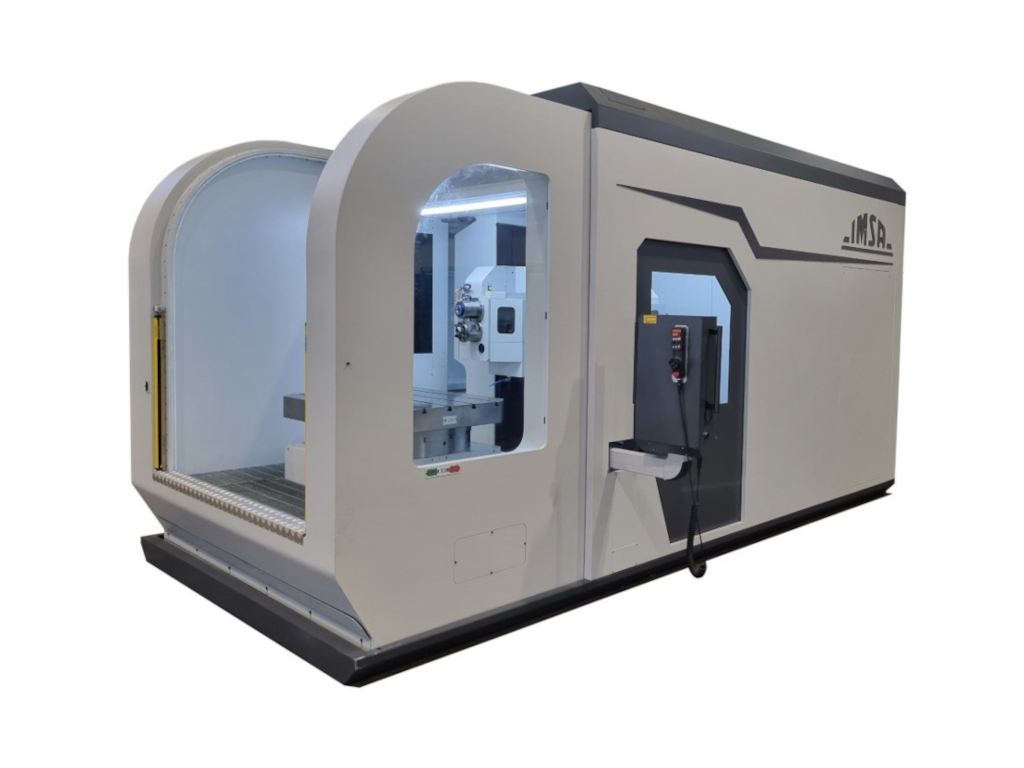

MF1000/2F with Rotary-Tilting Table

Gun drilling and milling machine for small to middle-size molds with complex waterlines. Straight (3-axis), single-angle (4-axis) and compound-angle (5-axis) drillings: this machine version is equipped with a rotary tilting table.

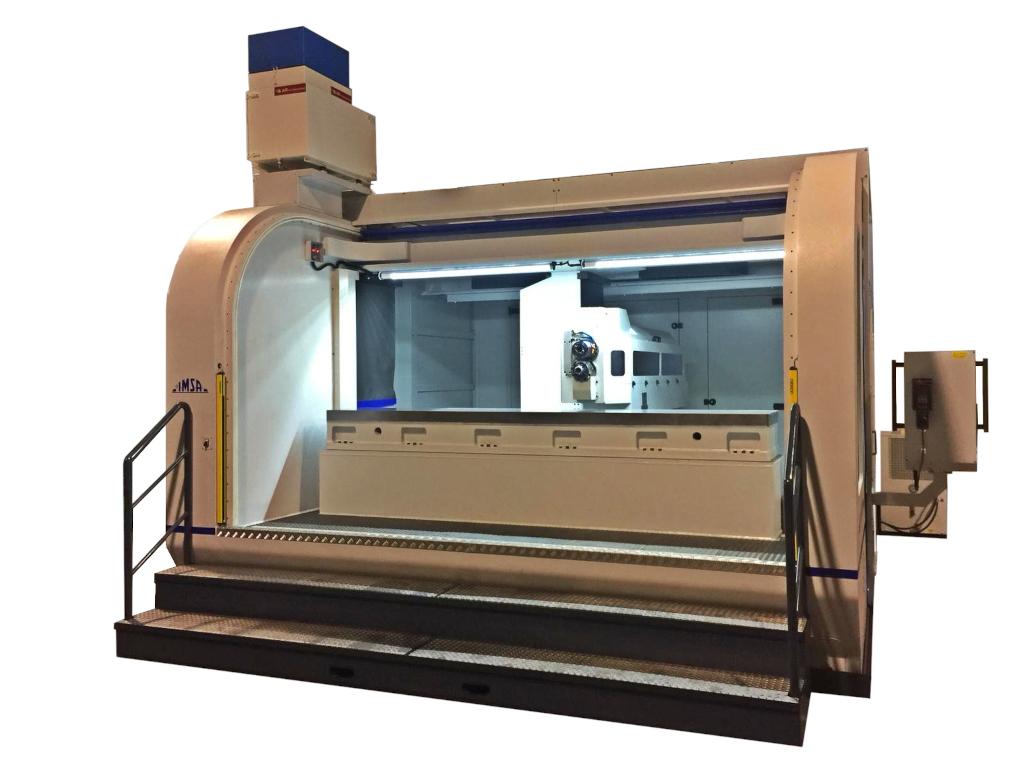

MF1750 EVO

“GUNDRILLING AND MILLING IN SINERGY”: EVO-Series Gundrilling and Milling Center for molds that require multiple-axis waterlines. Vertical Gantry structure. The Gun Drill Center MF1750EVO is suitable for large molds up to 30 / 40 / 45 tonnes, depending on the selected table. A workpiece of diameter 4,300mm max can rotate inside the machine structure.

MF1250/2FL

Gundrilling and milling machine for small to middle-size molds with complex waterlines. Straight, single-angle and compound-angle drilling: this machine version is equipped with a rotary tilting table.

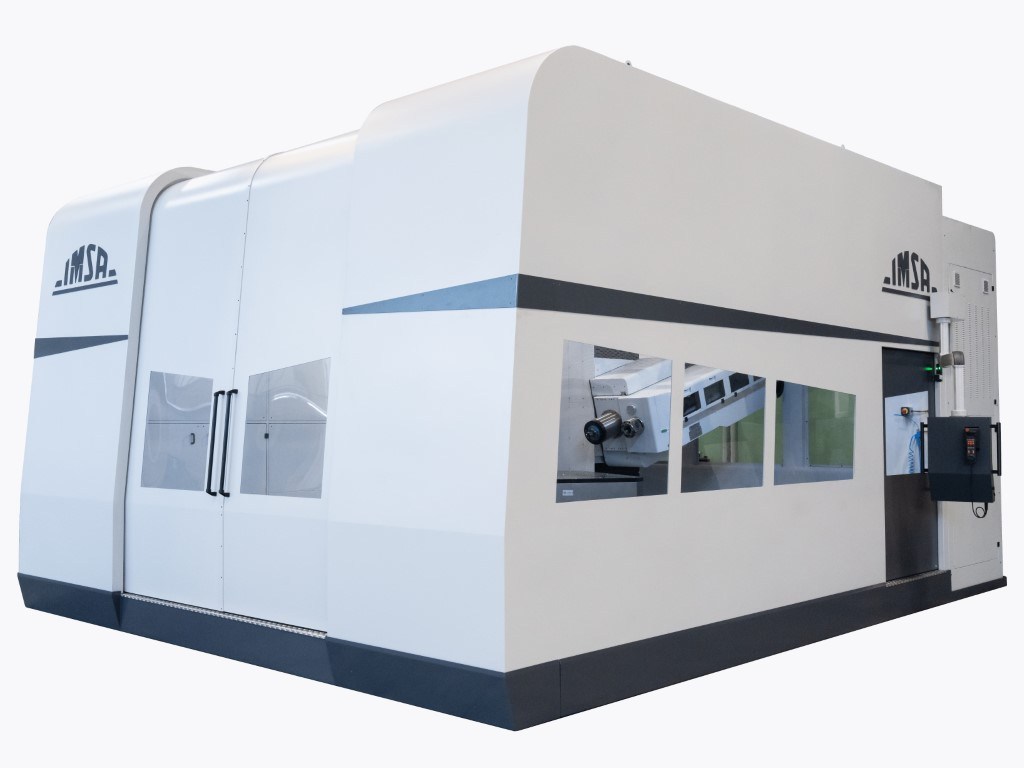

MF1600 S2

The milling and gun drilling center IMSA MF1600S2 is designed for manufacturers of tool and dies up to 30 tons in the mold making industry. T-shape machine concept: translating table and transversal movable column.

MF1300/4P EVO

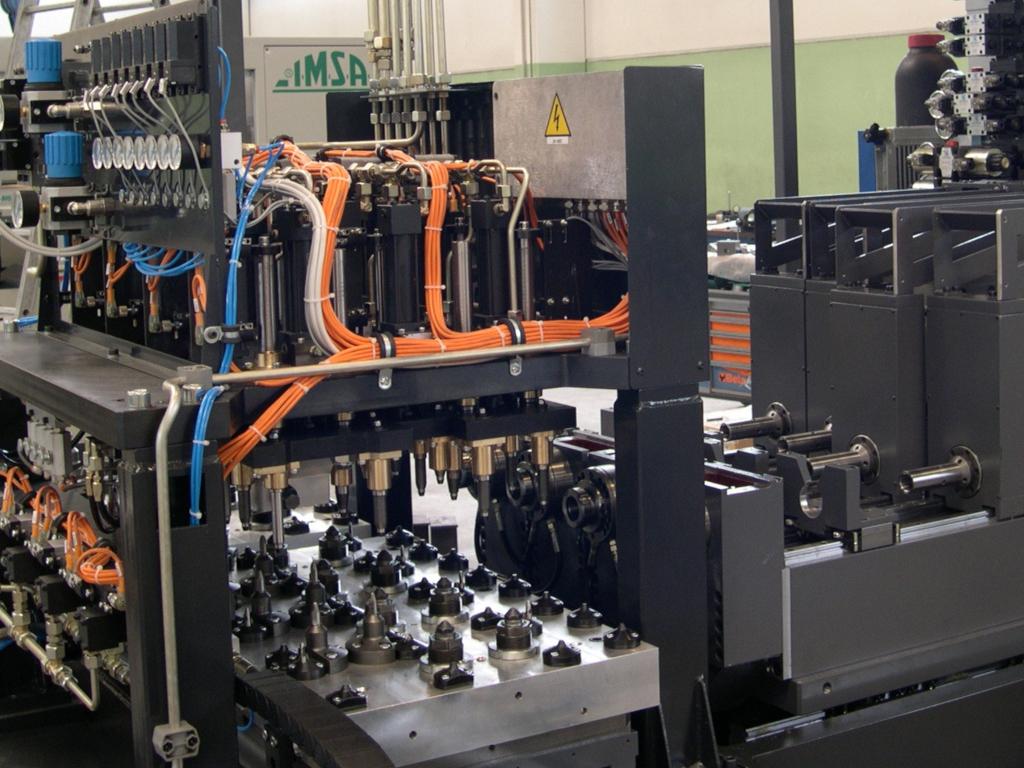

“TOP AUTOMATION IN GUN DRILLING”: EVO-Series Gun Drilling and Milling center, equipped with IMSA’s 4-station Gun Drill Changer

MF1350 EVO

“GUNDRILLING AND MILLING IN SINERGY”: EVO-Series Gun Drilling and Milling Center for molds that require multiple-axis waterlines.

MF1500 / 3000

Customized gun drilling and milling machine with increased horizontal travel.

MFT 750 /6 CR

Small diameter centerline deep drilling machine for cylindrical parts, especially for the medical industry. Single spindle. Method: by gun drill tool. Workpiece in counter-rotation. Drilling diameters: 1,5 – 6 mm. Drilling depth: max. 120mm approx. for Ø 1,5 – 3 mm; max. 750 mm for Ø 3 – 6 mm.

MFT 750 /12 CR

Centerline deep hole drilling machine for cylindrical parts, especially for the medical industry. Single spindle. Method: by gun drill tool. Workpiece in counter-rotation. Drilling diameter range: 3 – 12 mm. Dilling depth: (160 x Ø) max. 750 mm.

MFT 500CR – MFT 1000CR – MFT 1500CR

Centerline deep hole drilling machines. Single spindle. Drilling method: gun drill tool. Workpiece in counter-rotation. Drilling diameters: (4) 6 – 25 mm. Drilling depth max.: as per machine name, respectively 500 mm, 1000 mm, 1500 mm.