HIGH-TECH GUN DRILLING AND MILLING CENTER WITH 4-STATION GUN DRILL CHANGER

- For workshops that need to extremely optimize the profitability of the deep drilling phase, IMSA proposes its Gun Drilling and Milling Center MF1300/4P EVO.

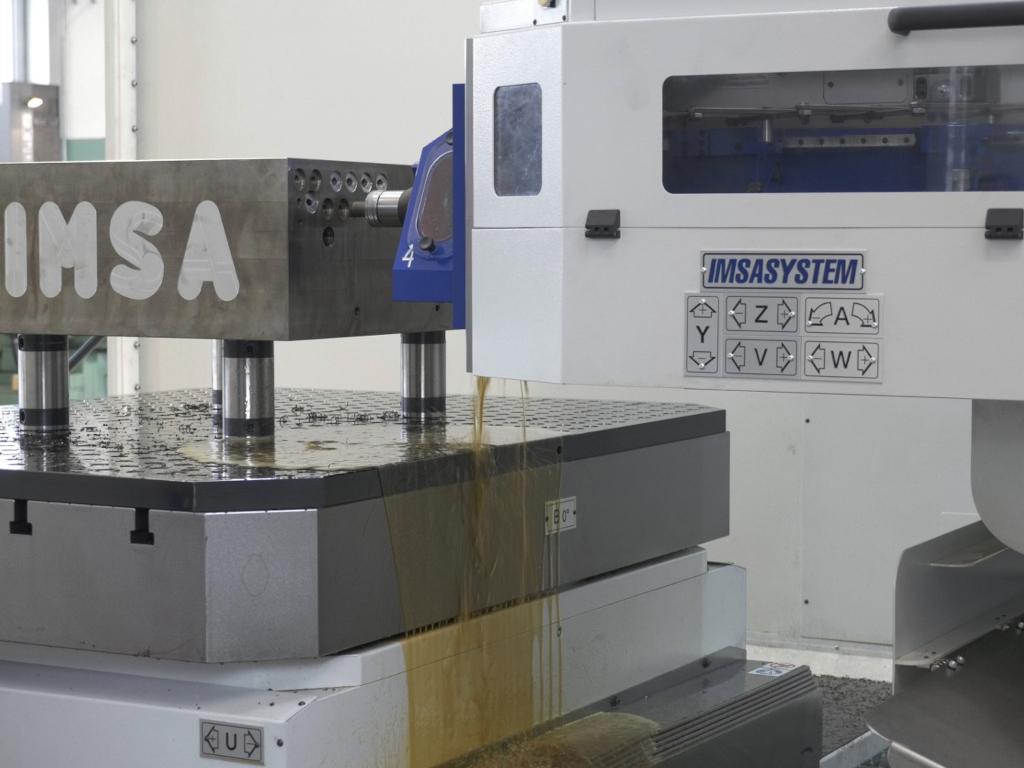

- Thanks to IMSA’s 4-positions gun drill changer, you can now drill 4x longer without interruptions or manage different gun drill diameters. Each gun drill unit has a chip box, steady rests, gundrill and guiding bushing. In this way, the correct alignments are retained.

- The MF1300/4P EVO is the evolution of previous projects: IMSA presented in 2009 its MF1100BB/6P, the first BB Series machine with interchangeable Gundrilling groups and MF1300BB/4P presented at the EMO trade show in 2015.

- Compound-angle machining in molds with complex cooling circuits is possible by combining table rotation and ram tilting movement.

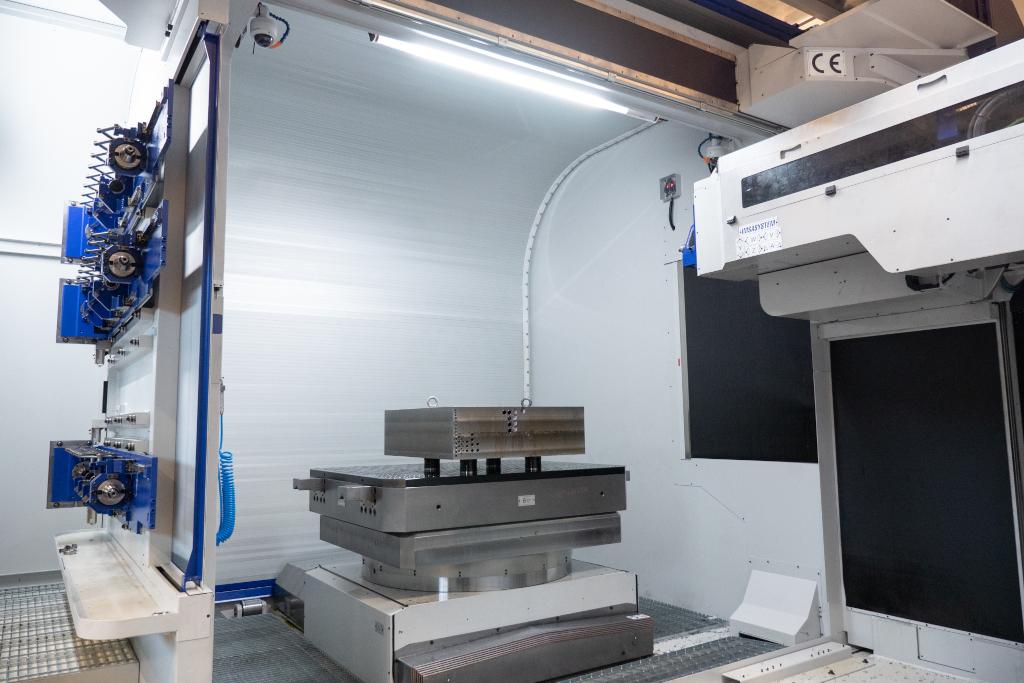

- MF1300/4P EVO is designed to drill molds up to 12 tonnes size. A workpiece of diameter 2750mm max can rotate inside the machine structure. 1200x1500mm table, infinite-position rotation movement, 500mm translation movement in approach to headstock. Deep drilling up to 1300 mm in a single cycle, diameter range from 5 to 40 mm solid.

- “EVO” Series: the well-known drilling performances of our BB-Series are here improved: MF1300/4P EVO’s gun drilling spindle has a power of 11 kW, 4200 rpm and is liquid-cooled.

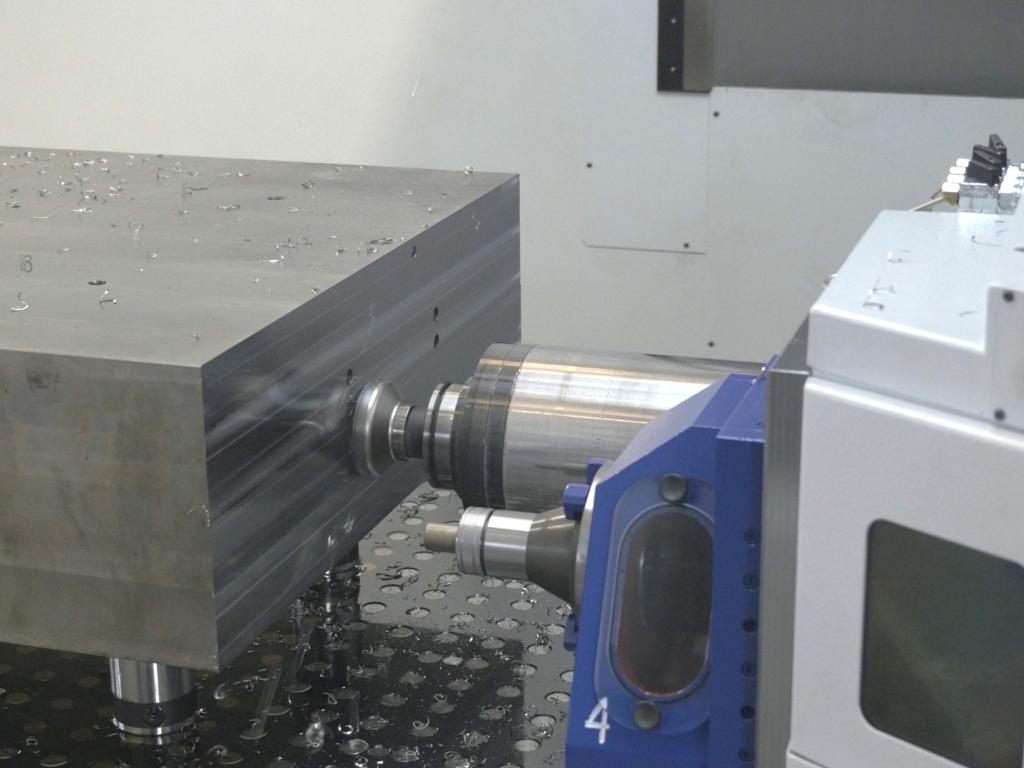

- The two spindles are separate and optimized: IMSA dual-spindle configuration for gun drilling and auxiliary machining. The switchover from gun drilling to milling and back is totally automatic, by M function, without any operator’s intervention.

- Horizontal milling stroke of 1100 mm obtained by combining the ram stroke (axis W 650mm) and the stroke of the milling shaft (axis Z 450mm).

- “EVO” Series: MF1300/4P EVO is equipped with a ISO50 liquid-cooled milling head with 29 kW power and 6000 rpm, for a maximum torque of 200 Nm. ISO50 automatic tool changer with 20 / 40 / 80 tool pockets.

- Performance is guaranteed in any vertical position thanks to our vertical gantry column structure, which supports the column both at the lower and upper end (16 times more rigid than a column guided only at the base).

- 4-Sides Machining Concept: the long transversal movements and the translating table increase the workpiece reachability, and enable a single workpiece setup in the table center. Advanced RTCP for the compound-angle machining. Two-spindle management with a single origin on the 4 faces. Specific IMSA/HEIDENHAIN function control the deep drilling process.

- The Gun Drilling Center MF1300/4P EVO can be equipped with a 2-position Pallet Changer and with a double screen with cameras into the machining area.