WHAT WORKPIECES REQUIRE DEEP HOLE DRILLING?

Molds for plastic, die casting, thermoforming, blow molding; aeronautical parts, hydraulic parts; mechanical transmissions; medical parts, and others…

Lightening, cooling, and optimizing the thermal and strain gradient in these workpieces are goals increasingly realized by drilling.

TABLE OF CONTENT:

What is deep hole drilling?

Helical drills

Gun drills

BTA/STS tools

Why a specific deep hole drilling machine?

Drilling machines operating with gun drills

BTA/STS method drilling machines

Deep hole drilling solutions for molds

Solutions for making on-center deep holes in cylindrical workpieces

WHAT IS DEEP HOLE DRILLING?

A hole is defined as deep when the length of the hole exceeds at least 10 times the diameter of the tool, up to lengths of 150 times the diameter and more, depending on how the tool is guided through the machine.

This is such an extensive range that it includes different systems and tools:

- Helical drills

- Gun drills

- BTA tools

HELICAL DRILLS

Nowadays, not only the traditional twisted steel drills are available, but also micrograin carbide helical drills, HSS drills, etc. …, with different and complex cutting edge geometries, with or without the internal passage of lubricant-coolant.

These tools also have very different characteristics from each other, typically covering drilling ratios such as 12:1, 20:1 (length: diameter) but even higher, such as 30:1.

Their manufacturers will know how best to advise you.

GUN DRILLS

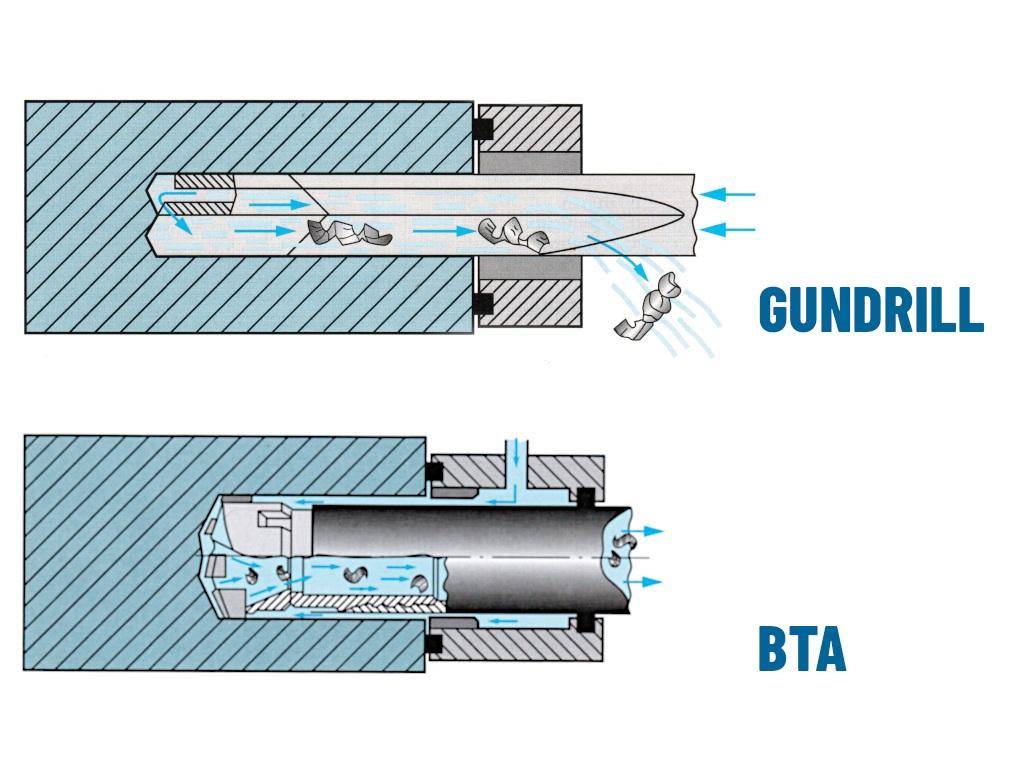

A characteristic shape, with a “V” groove along its entire length, distinguishes the gun drill, which has one or more central holes that carry the high-pressure lubricant-coolant to the cutting edge.

The geometry of the cusp has a non-symmetrical shape, working by rotating around its own axis: this is a single-cutting, non-self-centering tool, which absolutely needs a pilot hole or a drill bushing. After that, the tool guides itself by unloading the force on its own pads on its peripheral profile.

The lubricant-coolant is either full oil specific for deep hole drilling or emulsified water, also specific for deep hole drilling. The lubricant-coolant is driven away along with the machining chips along the “V” groove of the drill.

Regrinding the braze-welded cusp gun drill is a simple operation that can be performed independently every 40-80 m. Given the large number of possible regrinds, over its lifetime a gun drill is capable of drilling for more than 1200 m.

Gun drills with braze-welded single-cutting cusps (traditional) are available on the market, as well as gun drills with inserts: usually, on IMSA drilling machines these two types are used. Manufacturers also offer different types for special technical applications, on which they will know how best to advise you.

Gun drills should be properly supported every 40 times their own diameter. For example, we drill holes for a length of 120:1 relative to the diameter on one of our classic machines up to 1,000 mm equipped with 2 steady rests to support the gun drill.

BTA/STS TOOLS

Only usable on deep hole drilling machines, BTA/STS tools consist of a drill head screwed onto a pipe. Oil supply to the cutting edges is provided through an oil pressure head that feeds the circular crown created between the surface of the hole and the outer surface of the pipe on which the drill head is screwed. Chips and coolant are discharged by passing inside the pipe.

The large surface area available for oil passage promotes an excellent lubrication and cooling; in contrast, the passage clearance for re-entry is limited only to the inner surface of the pipe. This limits the use of this technology to drilling only materials with good machinability and with a sufficiently large diameter.

A drill bushing directs the BTA tool to the start of drilling. After that, the tool guides itself by unloading the force on its own pads on its peripheral profile.

The lubricant-coolant is either full oil specific for deep hole drilling or emulsified water, also specific for deep hole drilling. In this specific tool, the passage of the lubricant-coolant is characterized by high flow rates, with significantly lower pressures than in the gun drill method.

Since chips are discharged through the inside of the tool pipe, it is of paramount importance that the drill head performs an optimal chip-breaking action. Braze-welded, single-insert and multi-insert BTA heads are available on the market. Manufacturers also offer different types for special technical applications, on which they will know how best to advise you.

The drill pipe should be supported with appropriate vibration dampers, according to the tool manufacturers’ instructions.

Deep hole drilling requires a good combination between machine and tool, particularly in terms of vibration dampening capability and lubrication-cooling system: all IMSA’s BTA-method drilling machines are developed from this concept.

WHY A SPECIFIC DEEP HOLE DRILLING MACHINE?

Using a gun drill on a non-dedicated machine tool, such as a lathe, a machining center or a milling machine, necessarily requires a pilot hole, which you will make with a short helical drill.

Next, you will use a first short gun drill.

Then, if the depth of the hole to be drilled is greater than the cantilever distance tolerated by the gun drill, you will have to proceed in several steps, using a gradually longer drill, which you will insert manually into the hole from time to time.

This is obviously a slow and non-automated process, recommended only in the case of occasional machining.

The best results in deep hole drilling are related to the guidance of the tool to prevent it from bending, and to the adequate influx of lubricant-coolant to dissipate heat and push chips out of the hole.

Technological parameters such as feed, speed, pressure and flow rate are crucial for chip control in this kind of machining.

Why is drilling with a specific deep hole drilling machine different? A drilling machine is conceptually made to include everything that ensures optimal use of the gun or BTA drills.

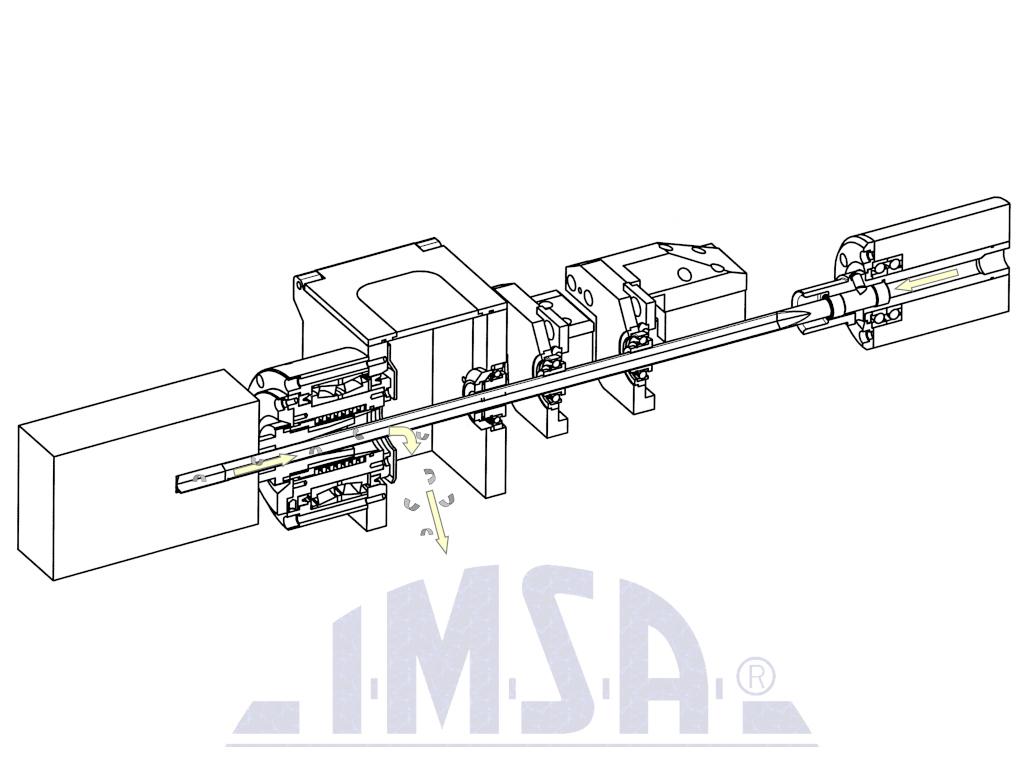

The machining unit of the drilling machine includes:

- a spindle with optimal power and speed for the application;

- movable steady rests, which on IMSA machines are self-spacing, for optimal support of the BTA drill or drill pipe;

- a fixed head (also called chip box) on the front of which there is a drill bushing that forms the “sight” for the drill, and through which coolant and chips coming out of the hole return, eventually falling onto the conveyor below.

The lubrication-cooling circuit of the drilling machine includes:

- pumps for the adduction of oil or emulsified water at the pressures and flow rates appropriate for the application;

- chip conveyor for collecting and separating chips and coolant leaving the holes;

- coolant collection tank;

- multi-level filtration system, for filtering 25 effective microns;

- refrigeration unit operating in parallel, in order to ensure the best operating temperature of clean oil.

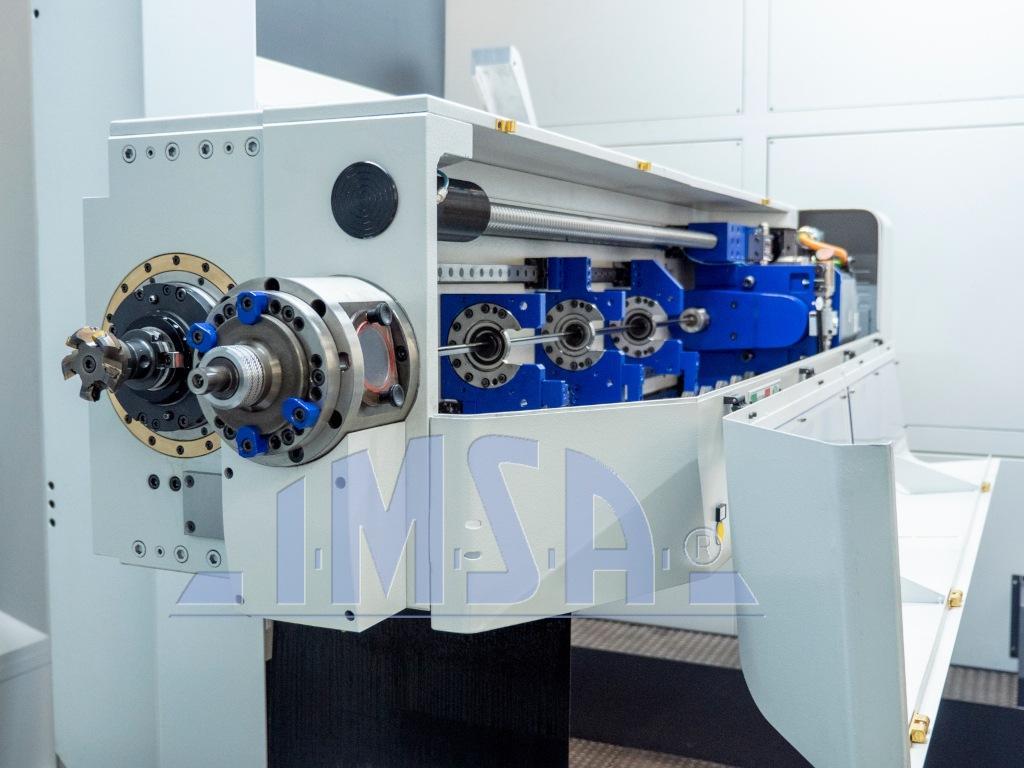

On an IMSA drilling and milling center, you can still drill with maximum-length gun drills on the deep hole drilling unit and, moreover, place other shorter-length drills of various types (HSS with/without internal coolant passage, relatively short gun drills to be used overhanging, etc…) in the ISO40/ISO50 tool changer, which you will use on the auto-switching auxiliary spindle.

DRILLING MACHINES OPERATING WITH GUN DRILLS

As we have seen, the “gun drill” method employs gun drills with internal lubrication of oil or emulsified water specifically for deep hole drilling, brought to the cutting edge at high pressure.

Chips and coolant are evacuated along the outer groove of the tool. After filtering and cooling, the coolant is returned to high pressures and reused in machining.

The range of lengths and diameters covered by our block drilling machines goes, depending on the models:

- from drilling diameters 4-18 mm for depths up to 800 mm;

- to deep hole drilling centers for molds up to 45 t, drilling diameters from solid 5-50 mm for max. depth 2500 mm.

The range of our gun drilling machines for round workpieces goes, depending on the models:

- from drilling diameters 1.5-6 mm for depths up to 750 mm;

- to drilling diameters 8-43 mm for depth 1500 mm.

IMSA solutions in the use of the gun drill allow average feed rates of 80-120 mm/min (in case-hardening steel), explaining how drilling with deep hole drilling machines is extremely more effective and economical than drilling with non-dedicated machines.

IMSA employs both gun drills with braze-welded cusp (traditional) and next-generation drills with interchangeable chip breaker inserts on its machines. Superior power and stiffness are able to develop drilling feeds as much as 50-70% higher, compared with the braze-welded equivalent.

BTA/STS METHOD DRILLING MACHINES

This drilling method is referred to as BTA or STS by different tool manufacturers.

As we have seen, in this method the oil path and the chip path are opposite to the gun drill method. An oil pressure head brings coolant to the cutting edge by passing outside the drill pipe; through the inside of the pipe, chips and oil are discharged, driven by pressure. Chips and warm oil at the outlet are separated; after filtering and cooling, the oil is returned to pressure and reused in the machining.

The range of lengths and diameters covered by our cylindrical workpiece drilling machines with BTA tools goes:

- from drilling diameters 18-51 for depths up to 1000 mm

- to drilling machines for drilling diameters 50-200 mm for max. depths 2000/3000 mm.

If the machinability characteristics are good, the average feed rates measured on IMSA MFTB series machines are 250-350 mm/min in case-hardening steel. Their characteristics of reliability and speed make these deep hole drilling machines particularly suitable for the production environment.

The tools used can be either braze-welded (not regrindable) or with interchangeable inserts. The interval between regrinds is highly variable depending on the material and feed rates.

DEEP HOLE DRILLING SOLUTIONS FOR MOLDS

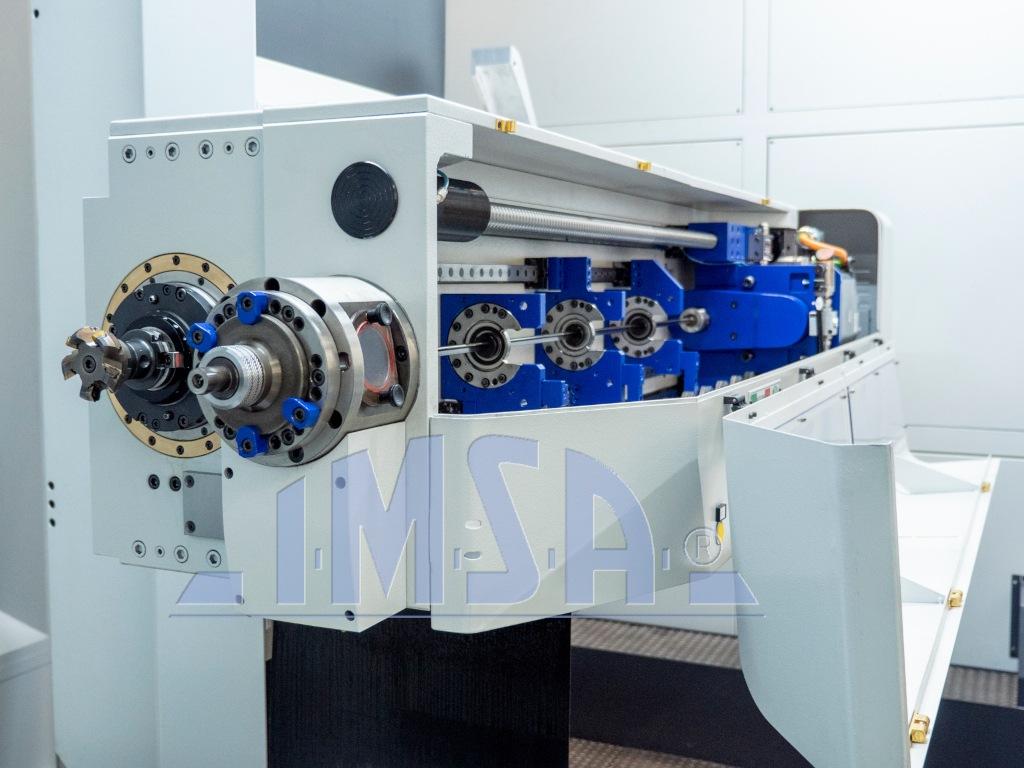

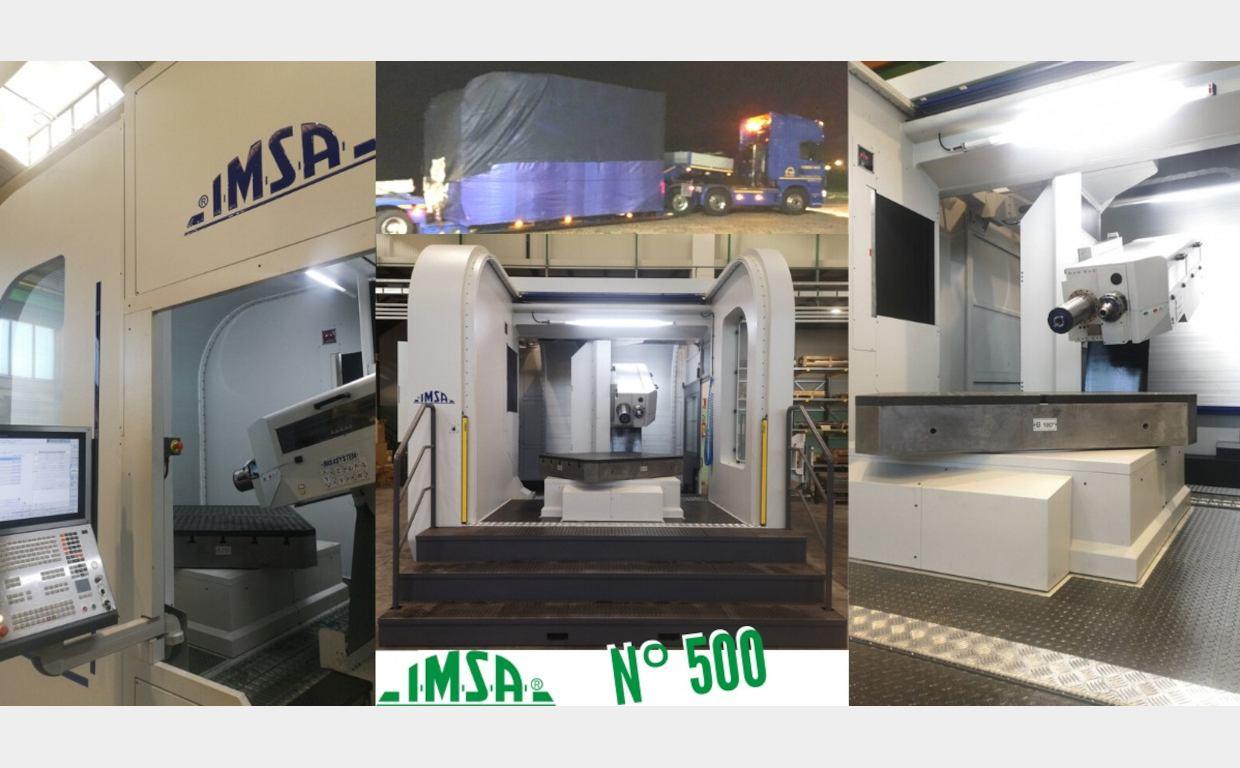

The range of IMSA gun drilling machines for molds (used for die-sets, tools, mold bases, mold inserts and drilled blocks in general) includes 3, 4 or 6 axis cnc gun drilling solutions which are ideal for small and medium-sized molds. Our range also includes cnc gun drilling and milling machines with 8-9 axes, perfect for medium and large-sized molds, used to create complex cooling channels with compound angle drilling and machining.

On the mold application, the IMSA team has always aimed to transform process needs into increasingly advanced deep hole drilling operational solutions.

A series of precautions borne out of experience, and the rigidity of our structures, enable an IMSA machine to drill traditional mold materials for 20 to 30 meters with a gun drill, before the drill needs to be grinded or replaced.

- The vertical Gantry column, supported at both the bottom and top, results in 16 times more stiffness than the traditional column structure supported only at the base;

- Machining units with two separate heads for deep hole drilling and milling perform switching between operations in fully automatic mode, therefore, even in unmanned shifts;

- The functions specific to the deep hole drilling process manage the electronic approach to the workpiece, read shear and thrust stresses to prevent drill breakage, and transform coordinates for inclined machining.

- The tables are conceptually made by providing for the handling and clamping required to handle the forces involved in deep hole drilling machining.

Look here at IMSA machines for molds and blocks

SOLUTIONS FOR MAKING ON-CENTER DEEP HOLES IN CYLINDRICAL WORKPIECES

Cylindrical steel alloy workpieces such as mechanical transmissions, grease nipples, automotive/aerospace rods, various barrels,… are often to be drilled with a blind or through-hole centered along their axis of rotation (on-center drilling). On the other hand, when holes parallel to the axis of rotation of the workpieces but not central to it are to be drilled, this is called off-center drilling.

For deep hole on-center drilling of cylindrical workpieces, IMSA offers a range of drilling machines using either the gun drill method or the BTA method, depending on the required diameters.

- The “U-shaped” structures of IMSA type MFT and MFTB drilling machines have zero drilling carriage height. The result of this solution is the cancellation of the bending moment that would normally be generated on the drill carriage, on the steady rests and on the oil pressure head, causing bending and vibration of the drill. The result is a considerable stiffness;

- Automatic workpiece loaders of various types are available;

- The functions specific to the deep hole drilling process read shear and thrust stresses to prevent drill breakage, and manage workpiece clamping pressures.

Look here at IMSA machines for on-center drilling of cylindrical workpieces

© I.M.S.A. S.r.l. – September 6, 2022.