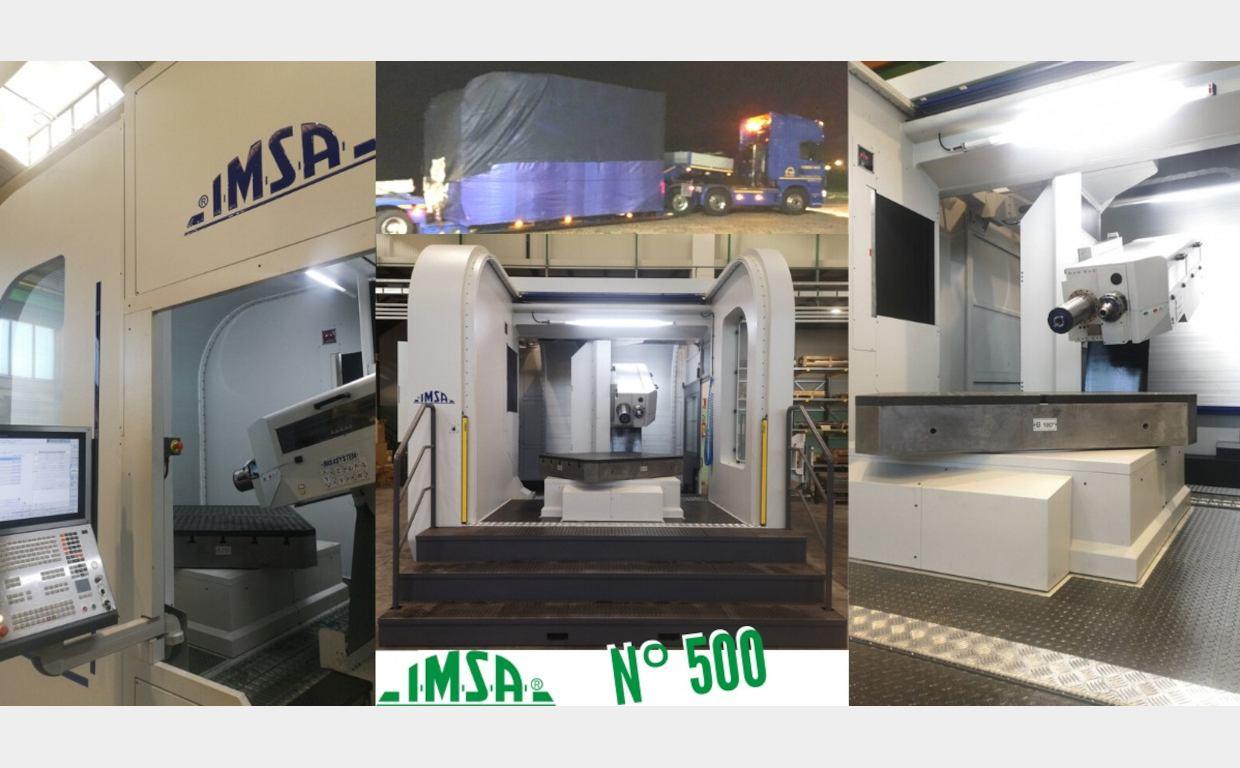

14/11/19 We are pleased to announce the installation of the 500th deep hole drilling machine by IMSA.

After the recent milestone of the 30th Company anniversary, this November brings another appreciated result. The five hundredth machine manufactured, which is an important achievement already, also coincides with the first MF1350EVO machine.

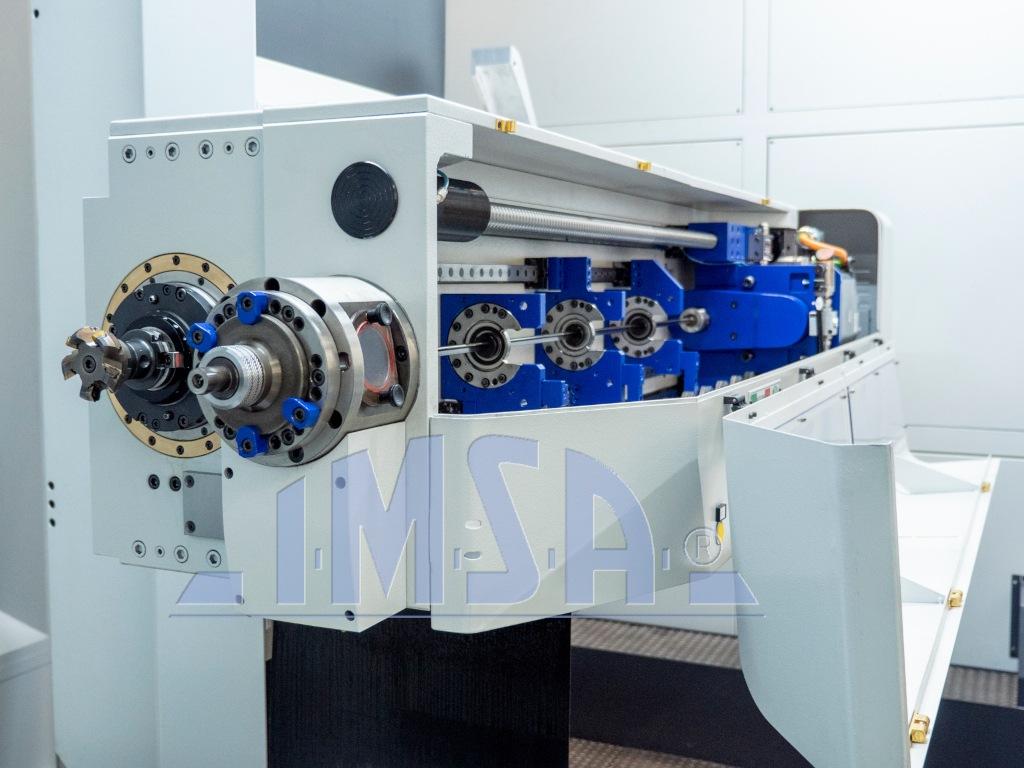

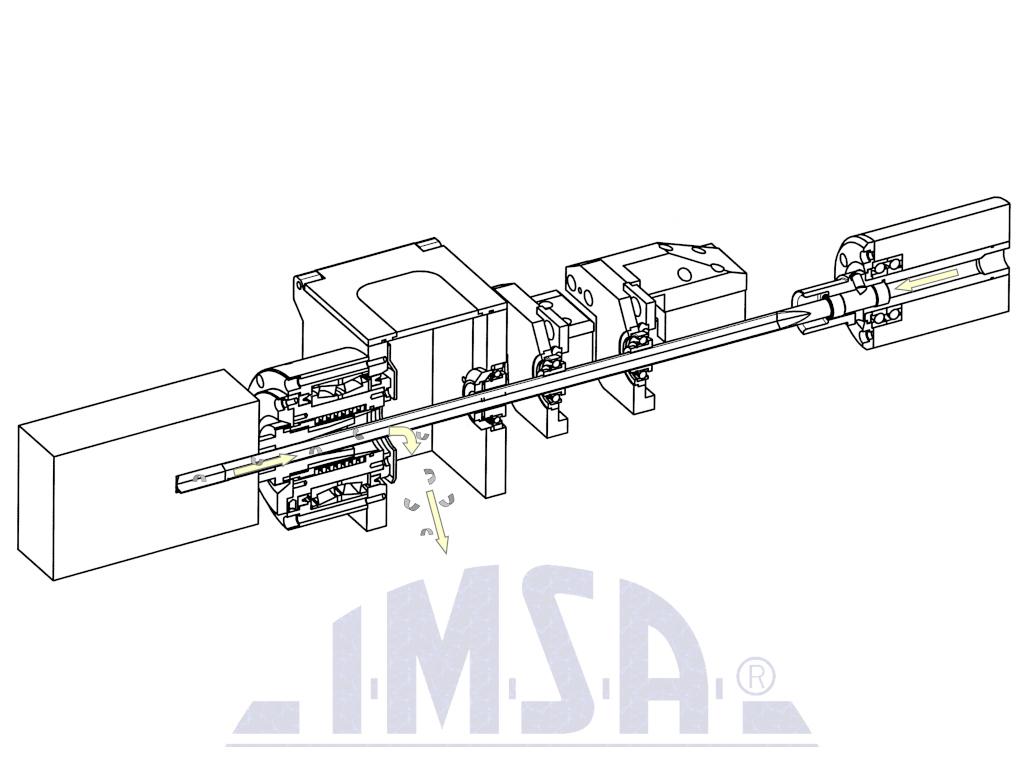

The MF1350EVO is a gundrilling and milling center for molds up to 12 tonnes, equipped with rotary table and tilting headstock. Two-spindle headstock (gundrilling spindle 11kW 4.200rpm; milling spindle ISO40 18kW, 6.000rpm). The first one has recently been installed at EXACTA STAMPI in Verano Brianza (Italy), a mold manufacturer who uses IMSA gundrilling machines since 1996.

Among these 500 machines manufactured so far, 410 are in service at plastic-injection mold manufacturers and subcontractors for deep drilling and milling in molds and blocks; the other 90 deep hole drilling machines are dedicated to cylindrical parts such as gear shafts, transmission housings, injectors, lubricators, drive valves, … in general, cylindrical workpieces that have to be drilled in their rotation axis.

In addition to the research & development for deep hole drilling machines, the company IMSA recently invested in automated vertical warehouse and machining centers, to improve the internal production processes, and in green investments such as the expansion of the solar panels installation (186 kWp), and the installation of a hybrid cooling and heating system managed by heat pump for the whole manufacturing facility. The presence of the owners’ children working in the company is another good sign of continuity from IMSA’s management.