Over the last few years I.M.S.A. has renovated its entire range of mould and block deep drilling machines and, notably, it has developed the new MF1350EVO model, a deep drilling and milling machine designed for machining moulds weighing up to 12t.

Translation of article from the Italian technical magazine “Costruire Stampi”, published March 2020

Constantly looking for increasingly high-performance, next generation technical solutions is crucial for retaining a competitive edge in today’s mould-making market. The process of deep drilling has also become more significant over the years due to the exponentially increasing complexity of mould cooling systems.

“Making highly evolved cooling systems — explains Luca Picciolo, Sales Manager for I.M.S.A. S.r.l. (Barzago, LC) — means building moulds that are cooled better and that, consequently, have increased productivity. Choosing a deep drilling machine that offers state-of-the-art performance means investing in a production unit that will provide immediate benefits and that will have a long shop floor life”.

It’s this logic that, over the last few years, has driven I.M.S.A. to remodel its entire range of deep drilling machines for moulds and blocks including the development of the new MF1350EVO in November last year, whose first edition was also the 500th drilling machine produced by the Italian company.

“The first edition of a new model, and our 500th production: we were thrilled with this dual achievement”, exclaims Picciolo. “Our EVO series, which currently consists of three models, evolved from our BB series of deep drilling and milling machines. An evolution our design team developed with all the know-how that characterises I.M.S.A.’s thirty-year history”.

That characteristic knowledge and experience can be found in this new, comprehensive, high-performance deep drilling machine, both in terms of renewing the machinery and expanding production opportunities.

DESIGNED FOR MOULDS WEIGHING UP TO 12T

MF1350EVO is a deep drilling and milling machine designed for moulds weighing up to 12 tonnes. It enables drilling of up to 1,350 mm in a single operation with diameters between 5 and 40 mm from solid material, as well as milling for preparing and completing holes (flattening, reaming, spot facing, threading, etc.).

The 1,200×1,500 mm rotary table can accommodate a workpiece of up to 12,000 kg at full rotational speed, but it is sized to handle a load of up to 16,000 kg as long as the speed is reduced during rotary positioning. The machine’s structure can accommodate blocks with a diameter of up to 2,600 mm.

The horizontal X axis effective stroke (minus the distance between the two spindles) is 1,900 mm and the vertical Y stroke is 1,250 mm. The vertical gantry structure offers rigidity, meaning performance is identical when drilling large diameters regardless of the vertical positioning.

Drilling and compound angle machining is performed by rotating the table and angling (from -20° to +20°) the ram.

The Heidenhain CNC’s advanced RTCP manages the trigonometric functions alongside specialised I.M.S.A. functions, allowing for machining on all four sides of a mould with just a single origin point.

Longer transverse strokes increase workpiece surface accessibility, allowing for single positioning at the table centre.

UPGRADED AND IMPROVED FEATURES

Why does the new model have EVO in its name? Picciolo explains: “The technical team at I.M.S.A. has fully updated our top-of-the-range drilling machines design, the “BB”, created in 2000. Several of our pre-existing flagship features have been improved; plus, we’ve made innovative modifications to meet and anticipate the current needs of mould-makers in the most practical way possible”.

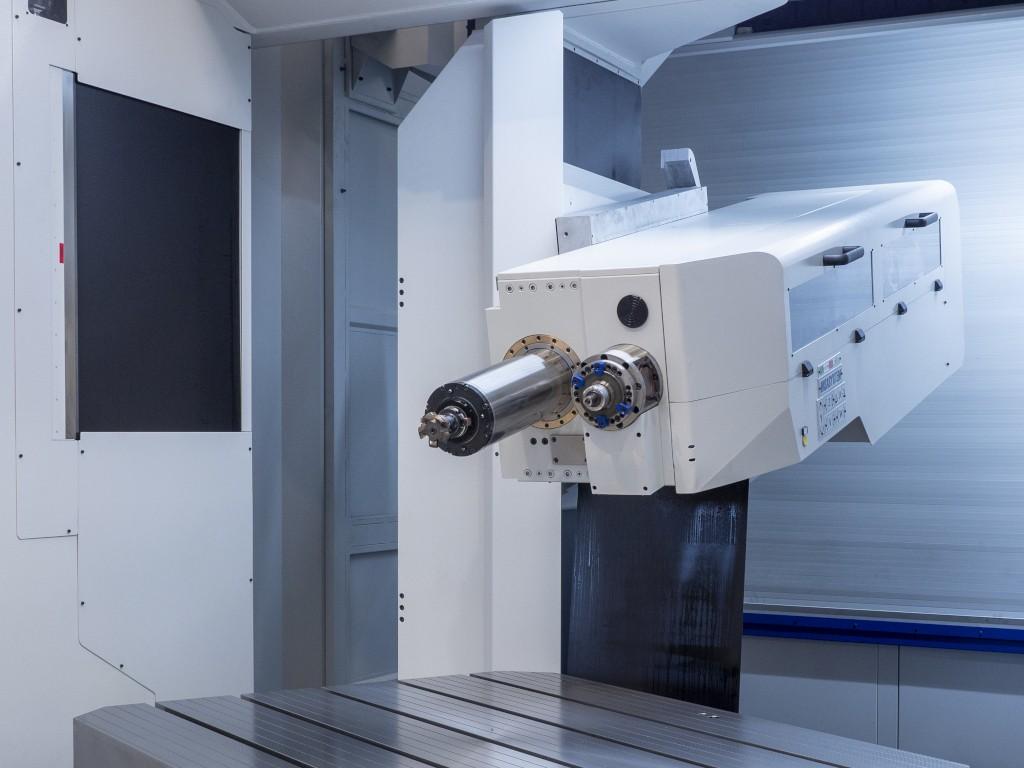

I.M.S.A.’s previous BB series of gundrilling/milling machines was already equipped with a vertical gantry column, i.e. a column structurally supported at both the lower and upper ends.

“This is one of our year 2000 innovations – Picciolo continues – providing sixteen time greater rigidity to the structure compared to an equivalent structure that only has a base support for its column. There are other MF1350EVO features that the previous MF1200BBLL model already had, but they’ve been updated and improved”.

Like the previous gundrilling machine, the new one has a self-supporting structure that doesn’t need foundations. It also enables compound angle machining through combining table rotation (B axis) with slide tilting (A axis).

“In this new machine, the A-axis rotation centre position has been moved closer to the table, making greater use of the machine strokes”, says Picciolo.

TWO NEWLY DEVELOPED SPINDLES

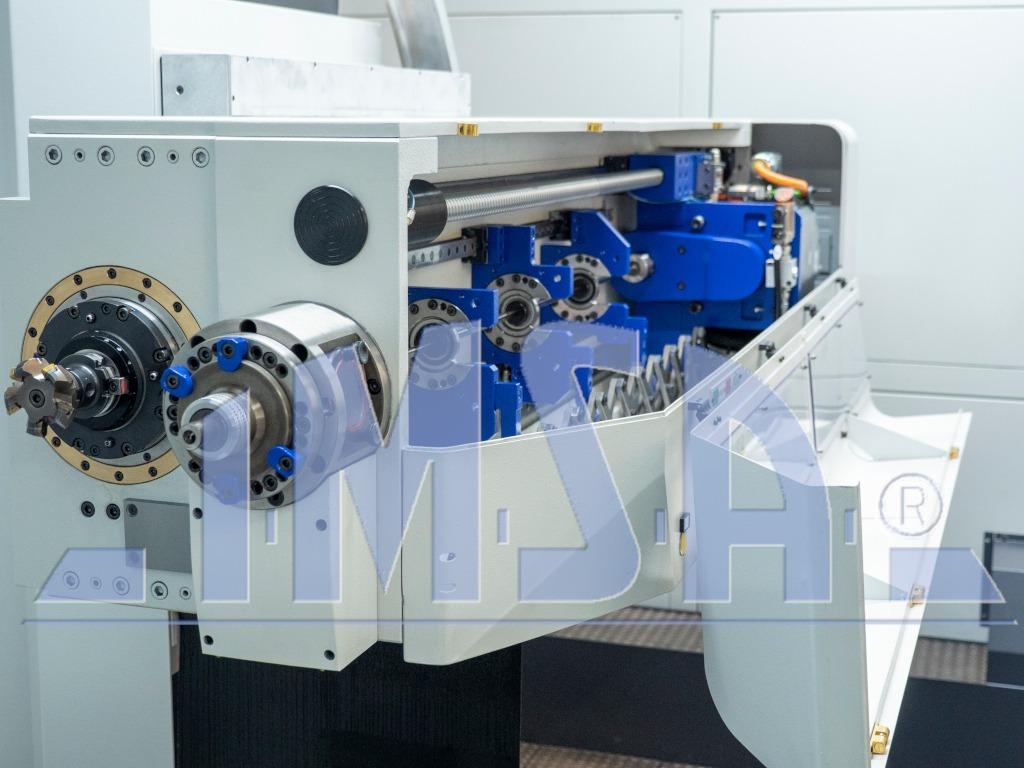

The spindle head ram houses two units: the deep drilling unit and the milling unit, both now equipped with liquid-cooled spindles.

The deep drilling slide allows for drilling holes with a diameter of between 5 and 40 mm from solid material with a maximum depth of 1,350 mm.

The spindle is driven by a low-noise Kevlar belt and an 11 kW liquid-cooled S1 vector motor with a speed of 4,200 rpm. The three gundrill steady rests have an “Imsautofocus” device for maintaining a mutual distance between the anti-vibration bushings throughout the drilling phase; in addition, the fixed chip box maintains precise constructional alignments which contribute to great results.

These results are further enhanced by the I.M.S.A. functions specially developed for deep drilling control, as well as the auxiliary coolant and oil filter systems, and the new pressure management that uses inverters and CNC programming.

For all contour machining with deep drilling, the ISO 40 milling head for the MF1350EVO is equipped with an 18 kW asynchronous S1 spindle motor with a speed of 6,000 rpm, direct drive, liquid cooling and permanent oil lubrication.

There are greater machining possibilities thanks to both the spindle type and the availability of through-tool oil lubrication, external oil through nozzle, and optional through-tool air cooling. The optional ISO 40 automatic tool changers finish off the new machine’s milling set.

STRUCTURAL RIGIDITY AND INCREASED POSITIONING ACCURACY

New and more powerful spindles would of course require a suitable structure. Luca Picciolo elaborates: “The increased stress created by the new spindles’ high performance is distributed over a structure that has been redesigned in several areas.

Next generation axis drives, optical measuring systems for X and Y axis positioning, a new Y-axis compensation system that further improves on the gantry column’s already high rigidity; optical measuring systems for the two rotary axes as well, A and B – (ram angling and table rotation, respectively) – both with hydraulic lock positioning. And there’s more: 50% faster speeds, flexible aluminium front door for greater durability, and lateral portholes with tempered glass. All these technical adjustments result in a high-tech machine that is uncompromising”.

THE THREE EVO SERIES SIZES

The new MF1350EVO joins the MF1450EVO which has been available for three years, for moulds weighing 6-12 tonnes.

“Although intended for similar sized moulds and both with identical deep drilling units — Picciolo clarifies — these two deep drilling centres differ fundamentally in their milling capabilities”. In fact, the MF1450EVO uses an ISO 50 spindle range with a 29 kW and 200 Nm motor with 6,000 rpm allowing for roughing and greater high stock removal milling.

For moulds weighing over 12 t, the largest machine in the EVO series is the MF1750EVO which, depending on the table chosen, can accommodate moulds from 20 to 45 t, and drill diameters of between 5 to 50 mm from solid material for a maximum depth of 1,750 mm (the number used in the I.M.S.A. machine name indicates the drilling depth, as usual) and uses an ISO 50 S1 430 Nm milling spindle with 45 kW and 4,500 rpm.