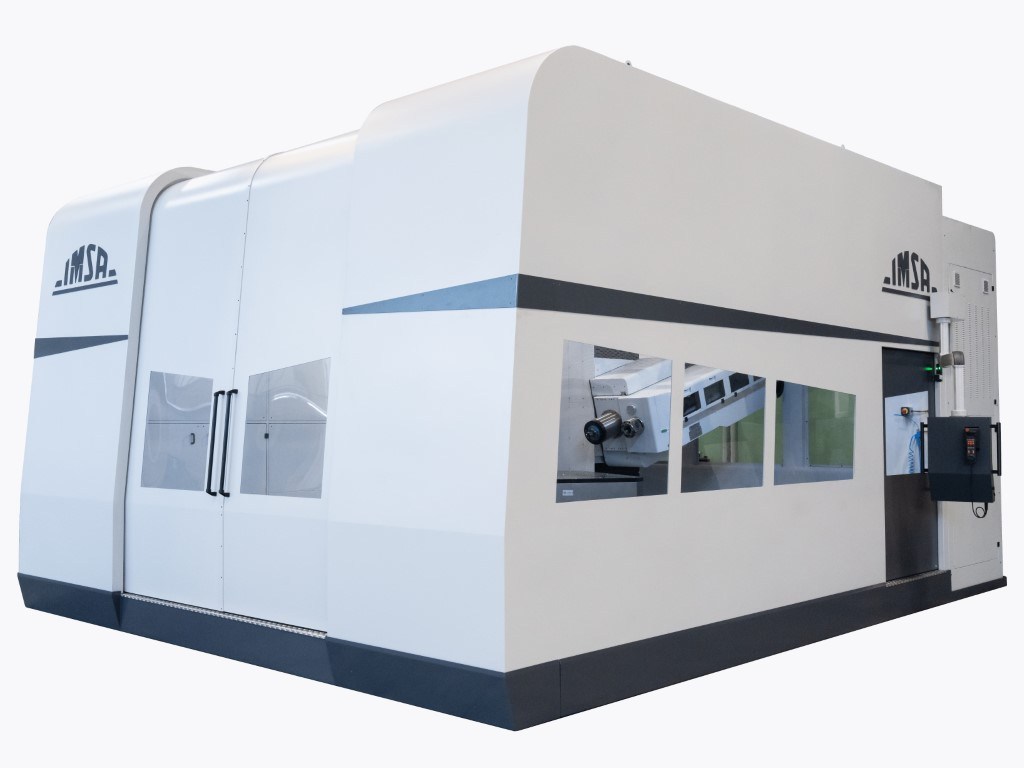

“Gun Drilling and Milling in Sinergy”

COMBINED DEEP HOLE DRILLING AND MILLING MACHINE

- The Gun Drill Center MF1750EVO is suitable for large molds up to 30 / 40 / 45 tonnes, depending on the selected table. A workpiece of diameter 4,300mm max can rotate inside the machine structure. Table has an infinite-position rotation movement, and a 1,000mm translation movement in approach to headstock.

- Orthogonal, single angle and compound-angle machining thanks to table rotation 360° (0.001°) and headstock inclination +20°/-20° (0.001°).

- 4-Side Machining: our new EVO series tables combine high loading capacity and smaller size, which facilitates 4-side machining with a single workpiece setup.

- Vertical gantry structure, resulting in better rigidity: bending moment 4 times lower than in low-supported column structure, 16 times higher rigidity. The gantry column ensures the best performances all along the Y axis travel.

- DEEP HOLE DRILLING: Drilling depth in single operation up to 1,750 mm. Drilling method: gun drill. Optimal drilling diameter range: from 5 to 50 mm solid.

- “EVO” Series: the well-known drilling performances of our previous BB-Series are here improved: MF1750EVO deep drilling spindle has a power of 15 kW, 4,200 rpm and is liquid-cooled.

- Specific IMSA functions control the deep drilling process.

- Temperature, pressure and coolant cleanliness are fundamental parameters to ensure continuous trouble-free gun drilling operations. MF1750EVO is equipped with the best solutions that can automatically manage those three parameters to the most suitable value.

- MILLING HEAD: MF1750EVO is equipped with a ISO50 machining head positioned on the tilting headstock, next to, yet independent from, the gundrilling axis. This independent axes system, distinctive feature of IMSA machines, provides the means for switching from drilling to milling and vice versa in just 8 seconds and does not require human intervention.

- Horizontal milling travel of 1,100 mm obtained by combining the headstock workpiece-approach (W-axis 600mm) and the milling shaft additional stroke (Z-axis 500mm).

- “EVO” Series: MF1750EVO is equipped with a ISO50 milling head with 45 kW power and 4,500 rpm, for a maximum torque of 430 Nm. Liquid-cooled spindle.