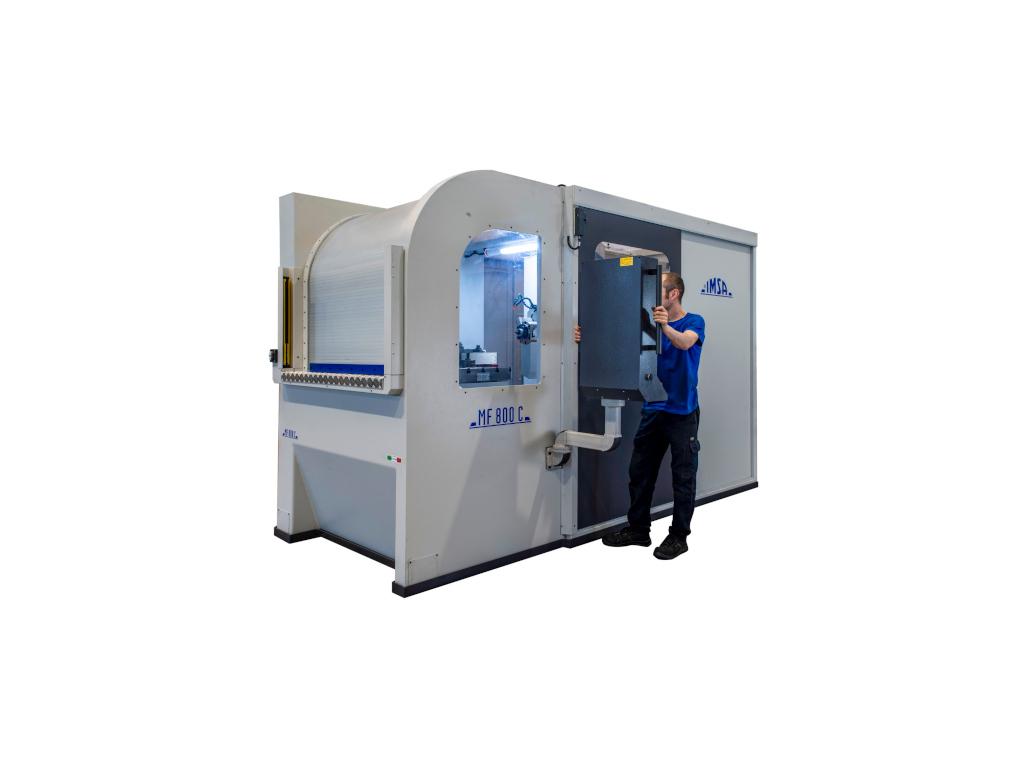

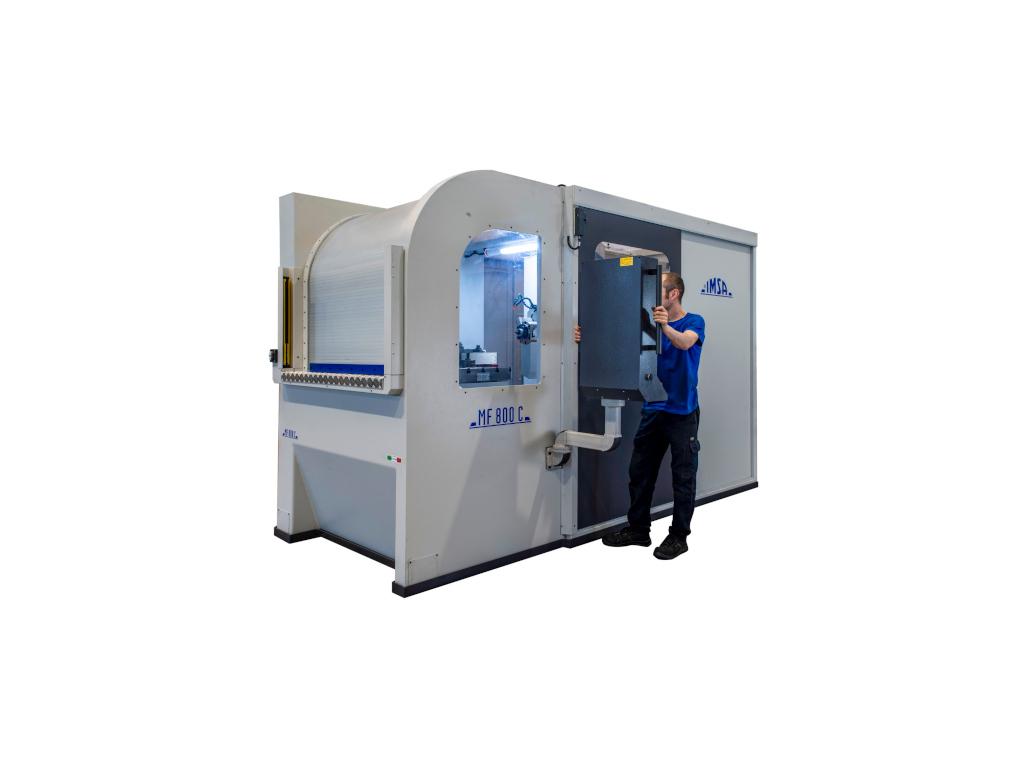

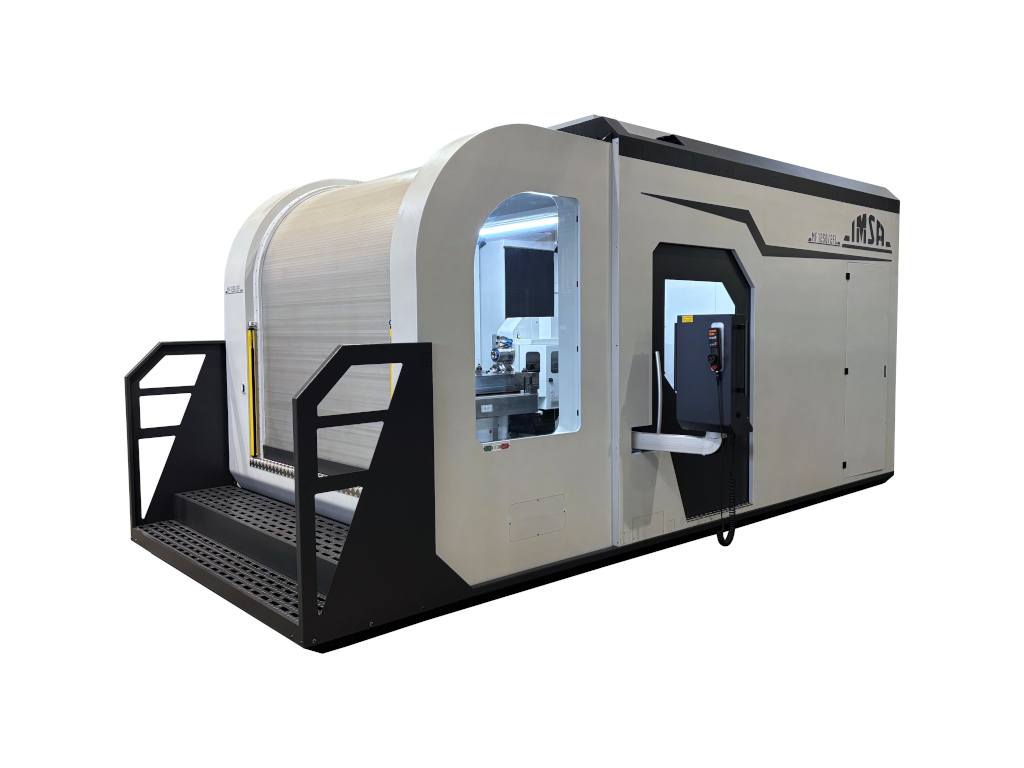

MF800C

IMSA’s simplest deep drilling machine for blocks and plates, and for off-center deep holes in cylindrical parts. Drilling depth max. 800 mm. Table load: 2000 kg (on optional rotary table); 4000 kg (on standard fixed table).

IMSA manufactured more than 600 deep drilling machines so far; among these, 450 are operating in the tool and mold making industry, in gun drilling job shops and moldmakers for plastic injection moulding industry and glass industry. Read a technical introduction about this holemaking technology in our article “The Deep Drilling Process”.

The never-ending quest to research/develop new technology solutions for our automatic gun drilling machines has always played a fundamental role for our team. Many of the recent innovations applied to deep drilling machines for moldmakers were developed by IMSA (Learn more in this article published in 2019 for IMSA 30th Anniversary).

FOR MOLDS UP TO 6 TONS APPROX

IMSA’s simplest deep drilling machine for blocks and plates, and for off-center deep holes in cylindrical parts. Drilling depth max. 800 mm. Table load: 2000 kg (on optional rotary table); 4000 kg (on standard fixed table).

IMSA simple 3-4 axes solution for blocks, mold inserts and plates.

The IMSA deep hole drilling machine MF1200D can also be used to drill centered and off-center deep holes in cylindrical parts.

Drilling depth in single operation max. 1200 mm. Table load 4000 kg.

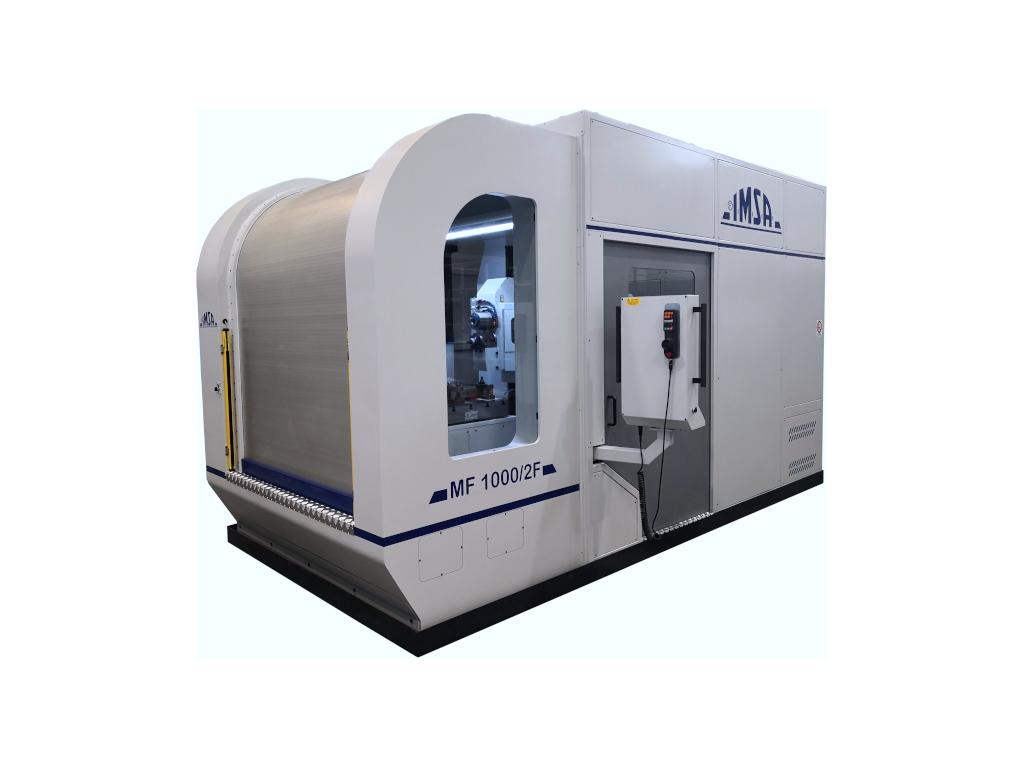

Gun drilling and milling machine molds and mechanical parts up to 2 or 4 tonnes, depending on the chosen table.

Machine version with rotary table, or machine version with rotary/tilting table.

Headstock with separate gun drilling and milling spindle, fully automatic commutation.

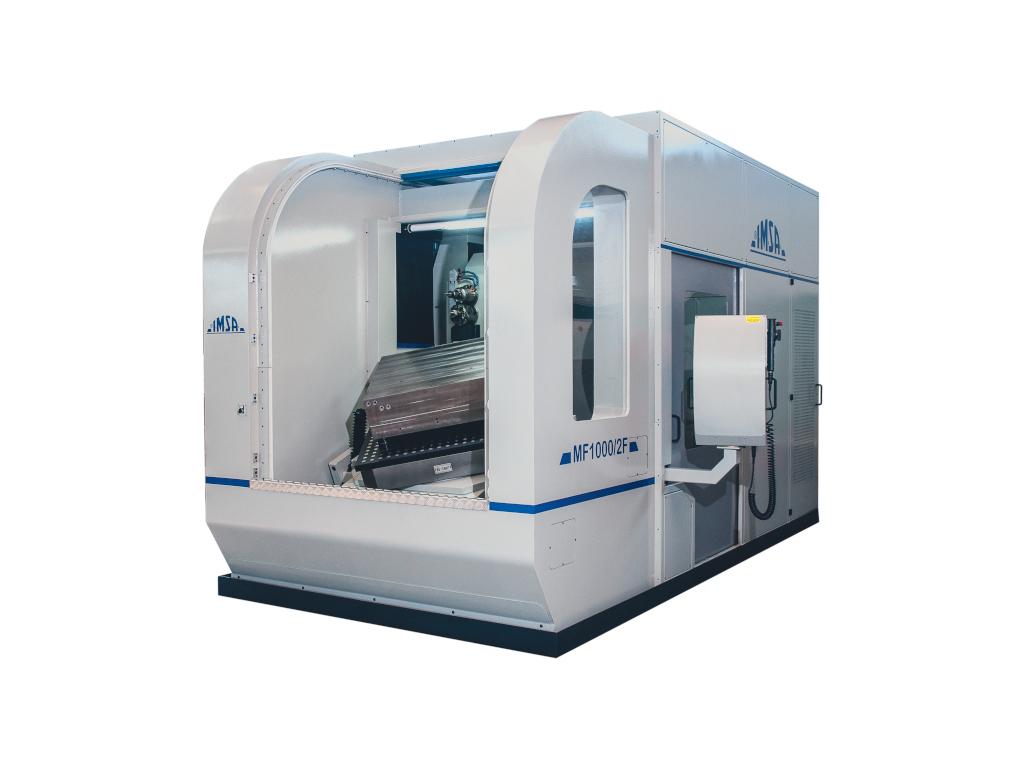

Gun drilling and milling machine for middle-size molds.

Headstock with separate gun drilling and milling spindle, fully automatic commutation.

Straight and single-angle drilling: this machine version is equipped with a rotary table. Table load up to 4000 kg or 6500 kg.

Gun drilling and milling machine for middle-size molds with complex waterlines.

Headstock with separate gun drilling and milling spindle, fully automatic commutation.

Straight, single-angle and compound-angle drilling: this machine version is equipped with a rotary/tilting table. Table load 5000 kg.

Gundrilling and milling machine for middle-size molds with complex waterlines.

Headstock with separate gun drilling and milling spindle, fully automatic commutation.

Straight, single-angle and compound-angle drilling thanks to rotary/tilting table, load 6 tonnes.

FOR MOLDS UP TO 12 TONS APPROX

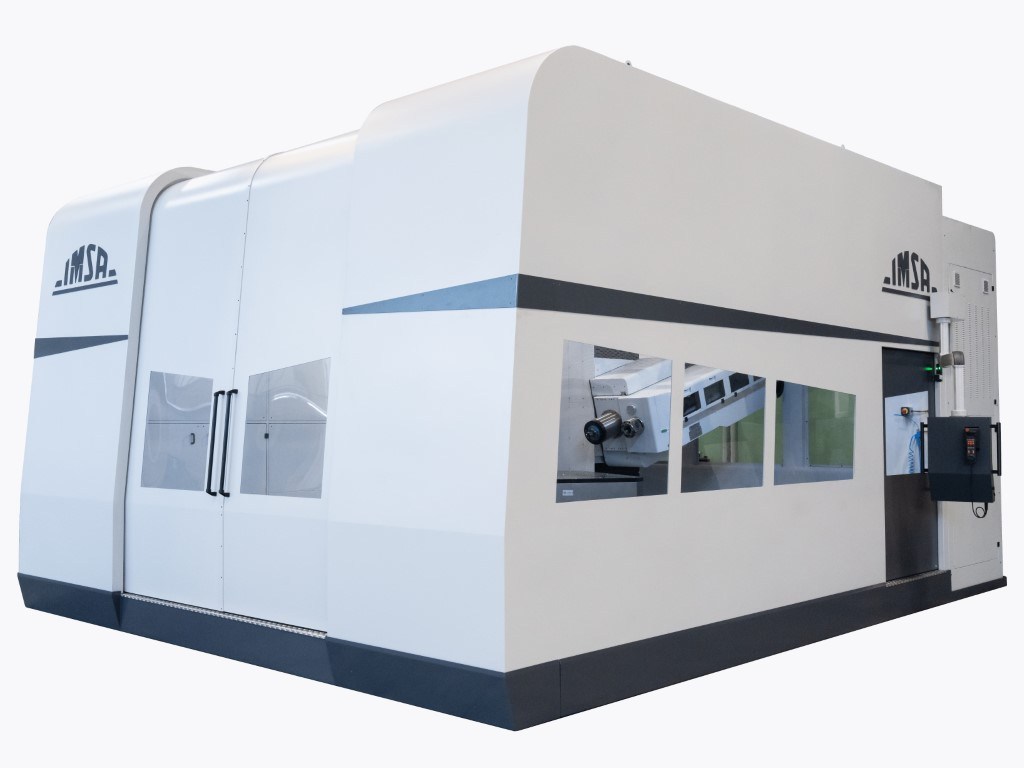

“GUNDRILLING AND MILLING IN SINERGY”: EVO-Series Gun Drilling and Milling Center for molds that require multiple-axis waterlines.

Tilting headstock with separate gun drilling and milling spindles, with fully automatic switchover requiring no operator intervention. ISO40 or ISO50 milling spindle.

“TOP AUTOMATION IN GUN DRILLING”: EVO-Series Gun Drilling and Milling center, equipped with IMSA’s 4-station Gun Drill Changer.

Tilting headstock with separate gun drilling and milling spindles, with fully automatic switchover requiring no operator intervention. ISO 50 milling spindle.

IMSA’s 4-station Gun Drill Changer enables automatic replacement of the gun drilling unit without operator intervention. Optional pallet changer.

TABLE LOAD FROM 20 UP TO 45 TONS

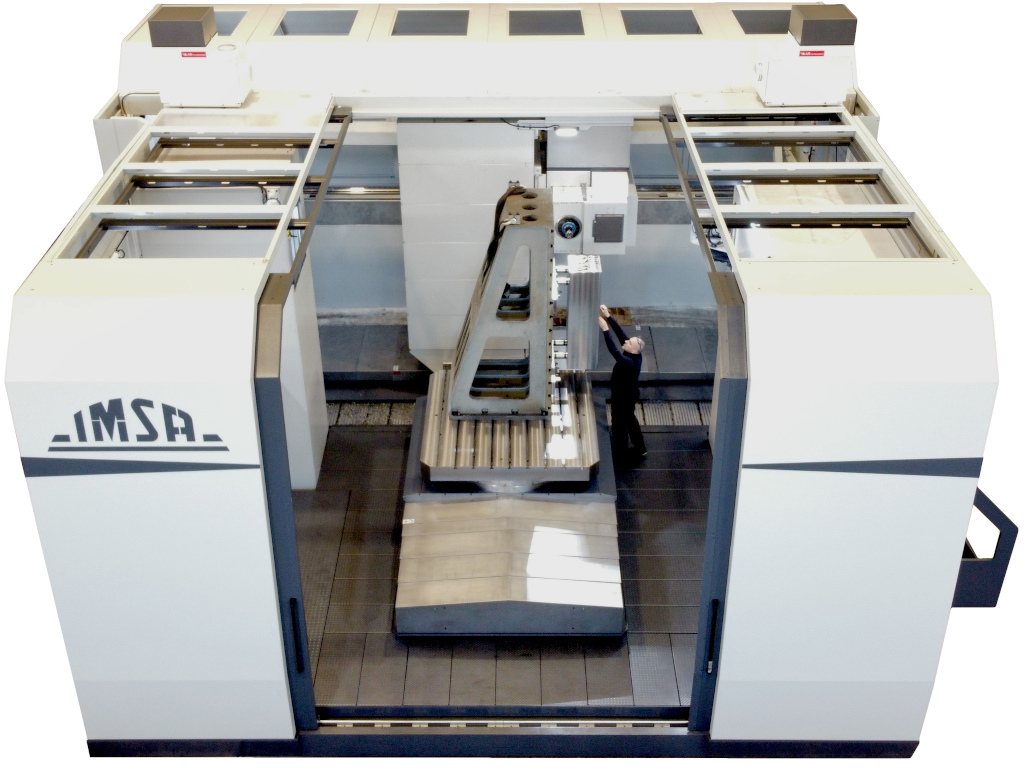

The milling and gun drilling center IMSA MF1600S2 is designed for manufacturers of tool and dies up to 30 tons in the mold making industry. T-shape machine concept: translating table and transversal movable column.

ISO50 35kW milling spindle. Two separate machining units, located on the same headstock carry out gun drilling and milling operations.

“GUNDRILLING AND MILLING IN SINERGY”: EVO-Series Gundrilling and Milling Center for molds that require multiple-axis waterlines. Vertical Gantry structure. The Gun Drill Center MF1750EVO is suitable for large molds up to 30 / 40 / 45 tonnes, depending on the selected table. A workpiece of diameter 4,300mm max can rotate inside the machine structure.

Tilting headstock with separate gun drilling and milling spindles, with fully automatic switchover requiring no operator intervention. ISO 50 milling spindle.

“TOP-AUTOMATION IN GUN DRILLING”: EVO-Series Deep drilling and Milling Center for molds, equipped with IMSA 5-station Gun Drill Changer.

MF 1650 /5P EVO is suitable for large molds and blocks up to 30 / 40 / 50 tonnes depending on the chosen table.

Tilting headstock with separate gun drilling and milling spindles, with fully automatic switchover requiring no operator intervention. ISO 50 milling spindle.

IMSA’s 5-station Gun Drill Changer enables automatic replacement of the gun drilling unit without operator intervention.

REQUEST INFORMATION

I.M.S.A. S.R.L

2023 I.M.S.A S.r.l | Tutti i diritti riservati | CF/P.IVA: IT01781790132 | Registro Imprese Lecco 01781790132 | REA LC 216013 | Cap. Sociale 35.000 € i.v.