NEW IN 2017

IMSA’s technical team recently made improvements on the spindles of MF1000C, MF1000/2F, MF1250/2FL machines. Thanks to these new spindles the machine performances both in gundrilling and in complementary machining have strongly increased.

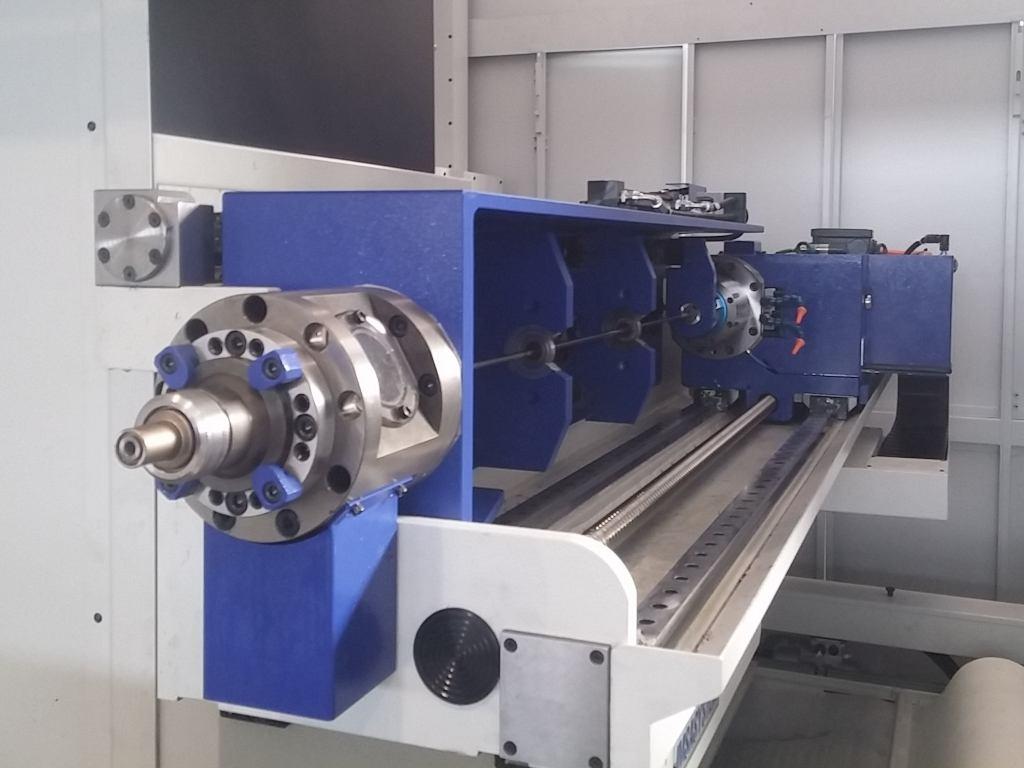

MF 1000C

Switchover concept: IMSA Exclusive Swing On Top system for the switchover gundrilling/milling operations.

New in 2017: ISO40 Single spindle, 13 kW (S1), max. 6.000 rpm, max. torque 115 N/m, with liquid-cooled Siemens vector-control motor.

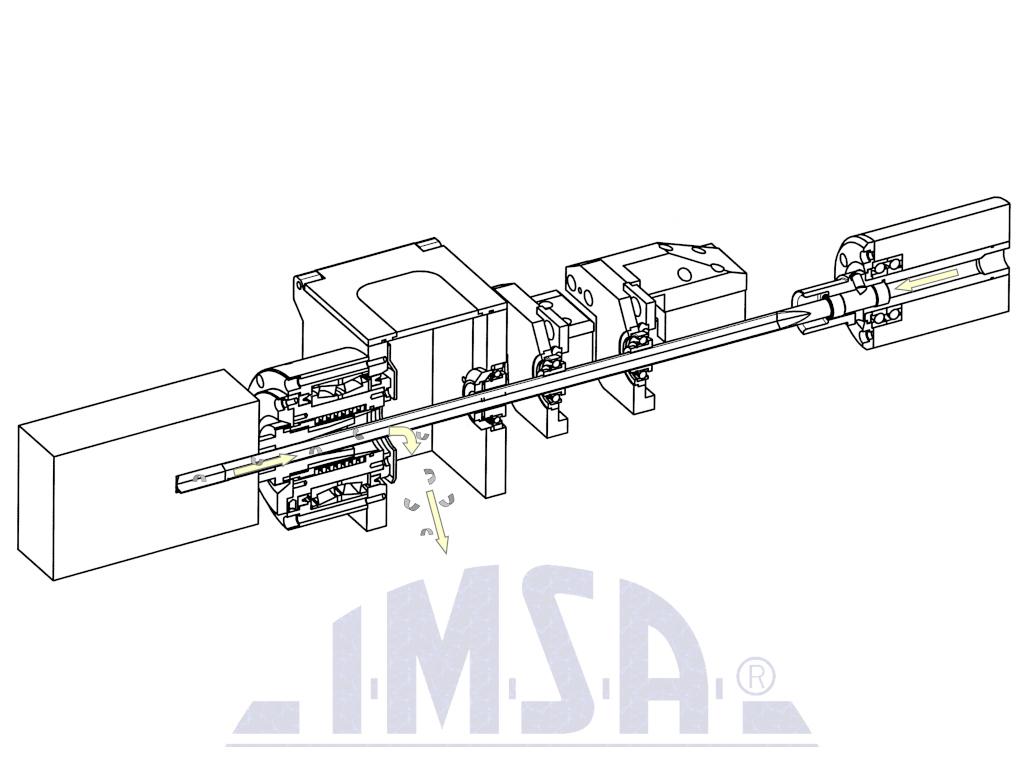

MF 1000/2F

Switchover concept: IMSA dual-spindle configuration. Separate gundrilling and milling spindles, automatic switchover by M functions. ISO40 Milling spindle, positioned on the same headstock above the gundrilling head.

New in 2017: Gundrilling spindle: 11 kW (S1), 6.000 rpm, with liquid-cooled Siemens vector-control motor.

New in 2017: ISO40 Milling spindle, 13 kW (S1), 6.000 rpm, max. torque 115 N/m, with liquid-cooled Siemens vector-control motor.

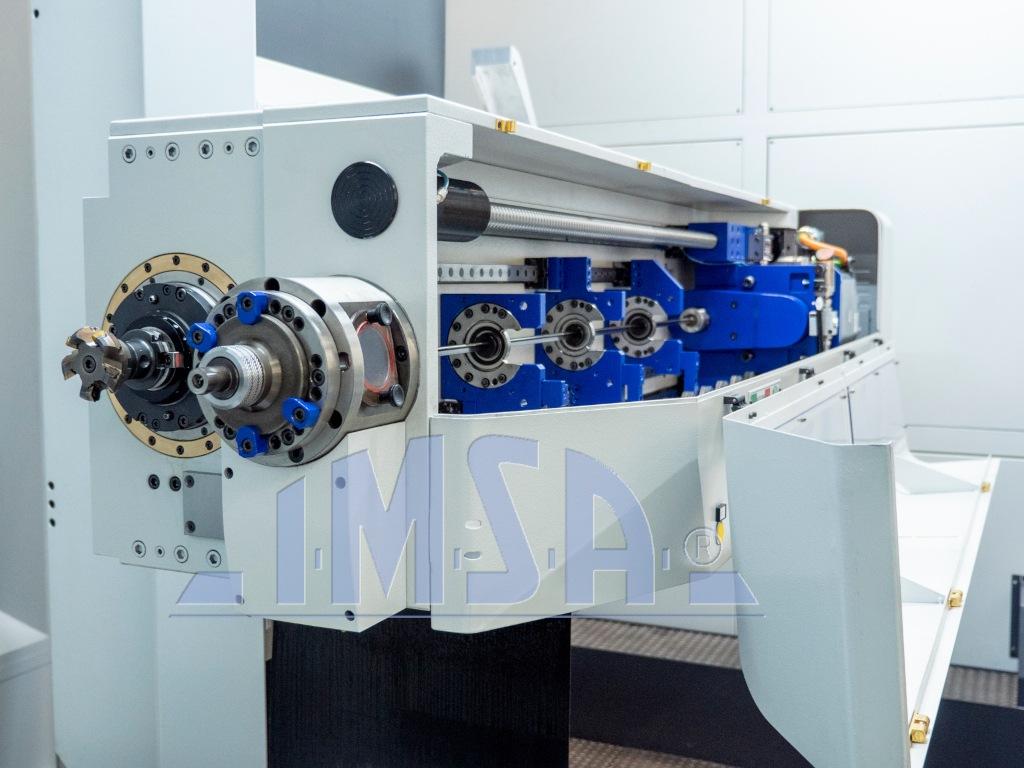

MF 1250/2FL

Switchover concept: IMSA dual-spindle configuration. Separate gundrilling and milling spindles, automatic switchover by M functions. ISO40 Milling spindle, positioned on the same headstock above the gundrilling head.

New in 2017: Gundrilling spindle: 11 kW (S1), 6.000 rpm, with liquid-cooled Siemens vector-control motor.

New in 2017: ISO40 Milling spindle, 13 kW (S1), 6.000 rpm, max. torque 115 N/m, with liquid-cooled Siemens vector-control motor.