PRESS RELEASE / EMO 2015:

GUN DRILL CHANGER ON DEEP DRILLING CENTER

STRONGLY AUTOMATES DEEP DRILLING PROCESS ON MOLDS

The lead-time for making a mold is the challenge that can strongly increase the level of competitiveness of manufacturers of plastic injection molds. Having cutting-edge deep hole drilling machines is fundamental to achieve this goal when these molds include complex waterlines.

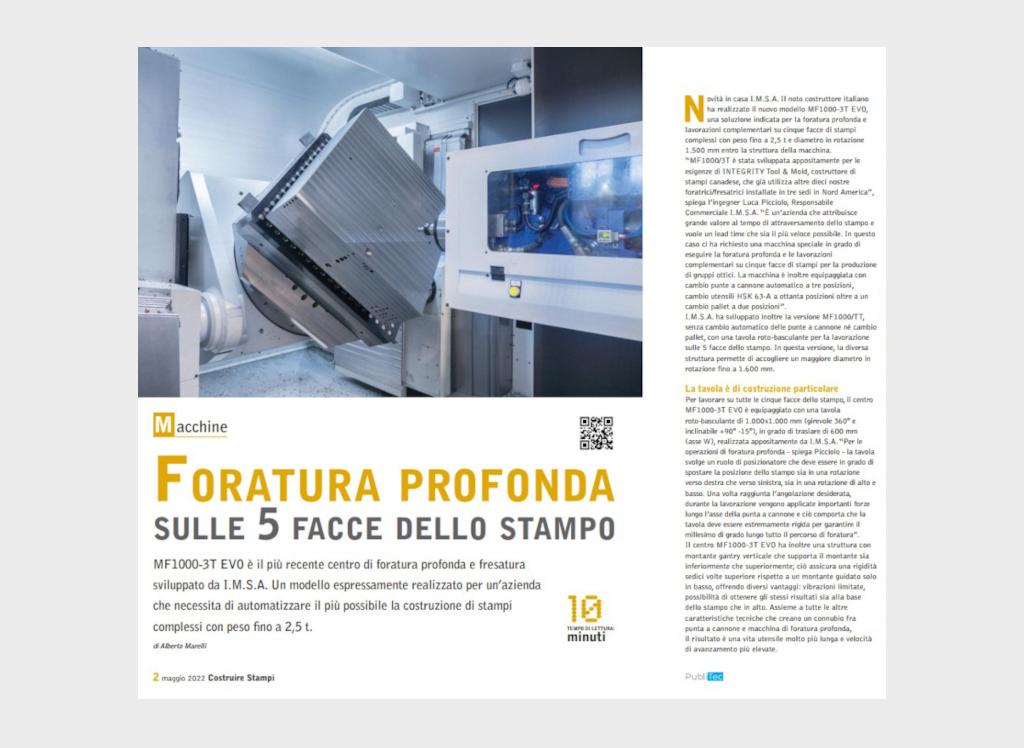

For workshops that need to drastically optimize the profitability of the deep drilling phase, IMSA presents at the EMO trade show the new Gun Drilling and Milling Center MF1300BB/4P suitable for molds up to 12 tons. Workpieces having a diameter 2,6 meters or smaller can rotate inside the machine structure. MF1300BB/4P executes deep drilling operations for a maximum depth 1,300 mm for a diameter range between 4 and 40 mm, with a 11-kW drilling spindle.

The distinctive feature of this new machine is the new automatic gundrill changer for 4 gundrill units. Each gundrill unit is composed of a gun drill complete with its chip box, drill bushing, support whipguides and ISO50 spindle taper.

Thanks to this system, drilling without interruptions is now possible for a 4x longer time in respect of an IMSA drilling machine of the BB series without gundrill changer. The gundrill unit storage can be equipped with 4 “twin” gundrills, thus extending the functionality when drilling long waterlines with holes of the same diameter, without need of interruption when the first gun drill requires resharpening; or the gundrill storage can be equipped for automatic operation with different gundrill diameters.

The gundrill units’ setup can be executed without downtime, while the machine is working, therefore even this phase has no impact on the machine profitability and productivity.

As the other IMSA deep drilling centers of the BB series, the new MF1300BB/4P has a vertical gantry-type structure to ensure the maximum rigidity; and is equipped with a milling spindle located besides the drilling unit on the same headstock. This concept enables switchover drilling/milling and back also when the machine is unmanned.

MF1300BB/4P has been equipped with a 29-kW ISO50 milling spindle for the machining operations complementary to deep drilling. This electrospindle enables to take advantage of the deep drilling center as much as possible also for the machining operations complementary to the holes.

We would like to thank DirectIndustry for shooting this video