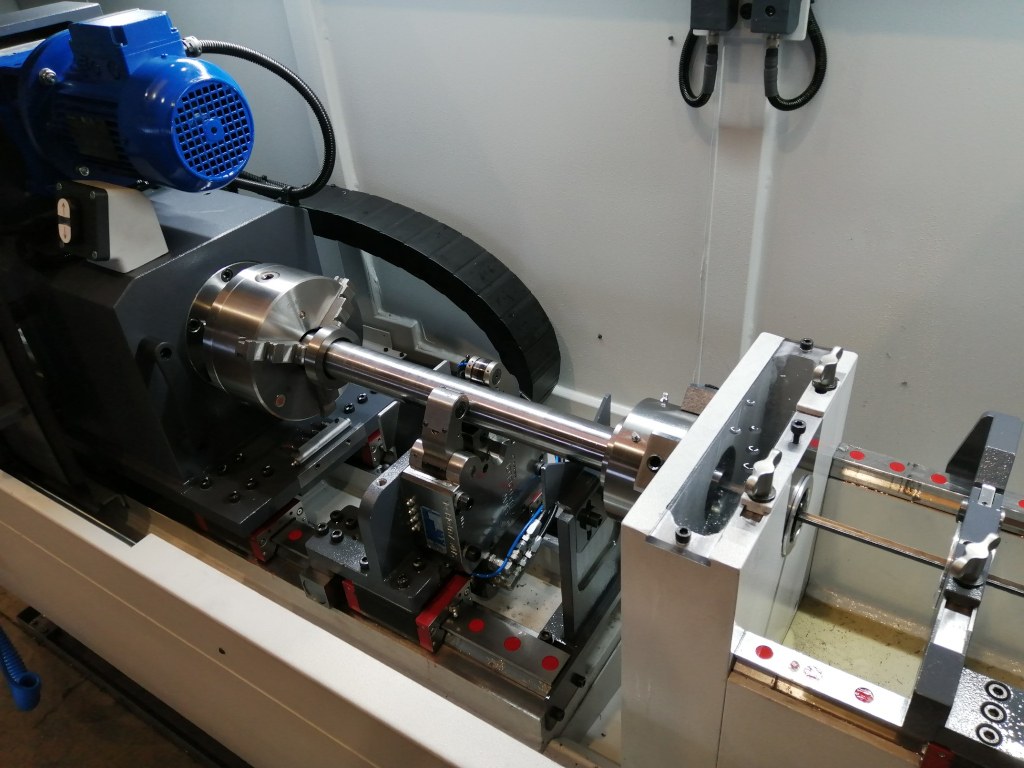

Single-Spindle

Gun Drill Tool

Deep hole drilling machine for steel shafts, for axial drilling of rotationally symmetrical parts.

- The IMSA MFT 600/12 EVO deep hole drilling machine is designed for the machining of cylindrical workpieces up to 600 mm in length, to be drilled axially with diameters ranging from 2 to 12 mm. Typical applications include medical components, temperature measurement probes, aerospace pins, and guide sleeves for molds.

- Deep drilling method: gun drilling.

- Drilling depth in one operation:

- For diameters up to 3 mm: maximum drilling depth is 40–50 times the diameter, using a spindle extension bar with the gundrill all inside the chip box.

- For diameters from 3 to 12 mm: drilling depth up to 160 times the diameter, with the gundrill supported by steady rests.

- Drilling spindle: 7 kW, 10,000 rpm.

- The workpiece is counter-rotated relative to the gun drill rotation to ensure maximum drill straightness. Counter-rotation speed: 150 rpm.

- Specific IMSA functions to control the deep drilling process:

- Electronic check of cutting parameters,

- Double electronic check against gundrill-breaking, by reading the cutting effort.

- Temperature, pressure, and oil cleanliness are key parameters for successful deep hole drilling. The MFT 600/12 EVO is equipped with the most suitable systems to manage these parameters:

- Oil delivery: high-pressure pump and digital pressure measurement,

- Oil clarification: two-stage filtration system,

- Cooling: heat exchanger for deep drilling oil.

Options:

- Automatic workpiece loader

- Automatic clamping movement

- Automatic door opening

- Workpiece steady rest