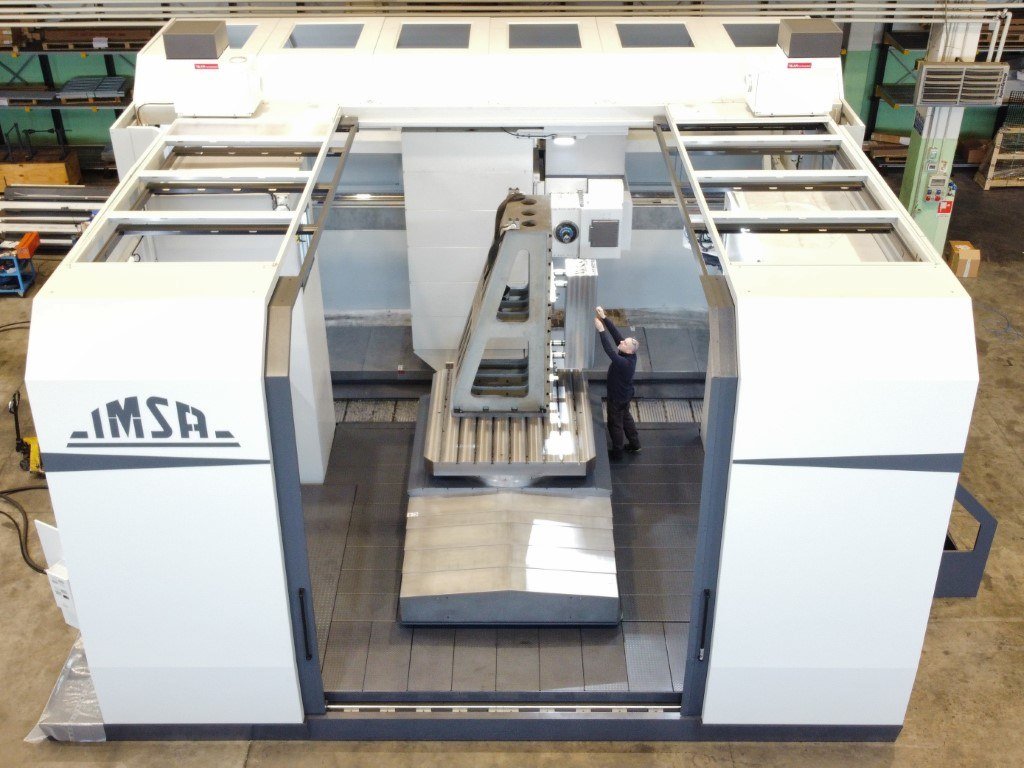

TOP-AUTOMATION GUN DRILLING AND MILLING CENTER

WITH 5-STATION GUN DRILL CHANGER

- The machine MF1650/5P EVO is designed for deep hole drilling and milling of large blocks, ideal for example for manufacturers of die-casting molds for aluminum and magnesium. Thanks to its rigidity and automatic gun drill changer, it ensures precise and safe operations in autonomy, optimizing time and guaranteeing high performance.

- Table load capacity 30 / 40 / 50 tons depending on the chosen version.

- Compound-angle machining to drill complex cooling circuits in molds is possible by combining table rotation and ram tilting movement.

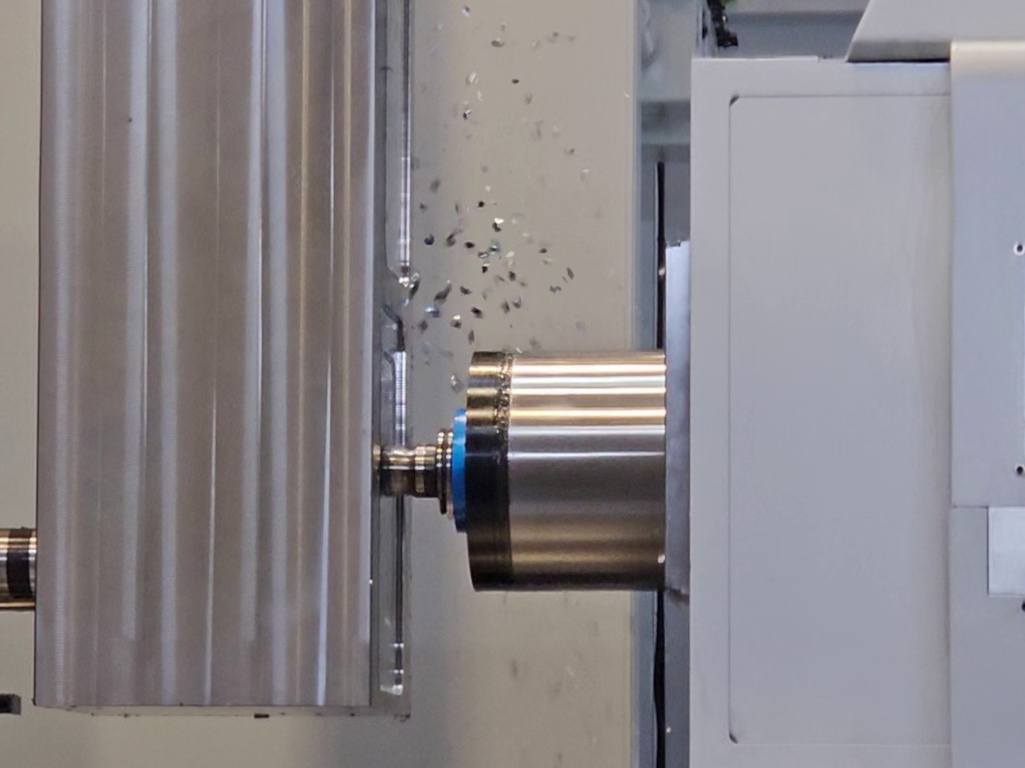

- Tilting ram with separate spindles:

- Gun drilling spindle 15 kW / 4200 rpm, liquid-cooled. Drilling depth in single operation up to 1650mm, optimal diameters 4-50 mm solid.

- ISO50 Milling spindle 45 kW / 4500 rpm on independent axis. The switchover between the two spindles is fully automatic and requires no operator’s intervention.

- Thanks to IMSA’s 5-position gun drill changer, you can now drill 5x longer without interruptions or manage different gun drill diameters. Each gun drill unit has a chip box, its steady rests, gundrill and guide bushing. In this way, the correct alignments are always retained.

- The gun drill changer system was introduced by IMSA in 2009 with the MF1100BB/6P, and then renovated on the MF1300BB/4P. Watch a series of pictures in this short video on Youtube: the story of IMSA gun drill changer.

- Besides ensuring high productivity in gun drilling operations, MF1650 /5P EVO is expressly designed to be a heavy-duty metal cutting machine, with a strong structure and large-designed transmissions. Different capacity ISO50 automatic tool changers are available in option.

- Movable column has a gantry design (i.e. double-guided with low front guide and up/back guide): IMSA vertical gantry structure results in much greater stiffness in respect to a traditional machine configuration with single lower guide.

- 4-sides machining concept:

- Long transversal movements and translating table increase the approach to workpiece, with a strong improvement in managing the mold.

- Advanced RTCP for compound angle machining.

- Single origin to manage the two spindles for the 4 workpiece faces.